The Sustainable Packaging Revolution: A Jabil Documentary

Henderson Island is an island in the South Pacific, about halfway between Chile and New Zealand. One of the world’s biggest marine reserves, from a distance, it looks like a scene from a movie: a screen of palm trees shading tropical shorelines, the pearly beach gradients into a lush, green jungle.

But even though Henderson Island is uninhabited and lies 3,000 miles from any major population centers, more than 19 tons of trash clutter its beaches.

This reflects a worrying trend: waste is ending up in places beyond human habitation. Microplastics are being found in every corner of the globe, from the ocean floor to Mount Everest. Unfortunately, plastic packaging makes up nearly half of all plastic waste generated globally, and less than one-fifth of it is recycled. The world needs a sustainable packaging revolution.

Jabil recently conducted a survey of more than 200 packaging decision-makers about their plans, challenges and opinions around sustainable packaging. When asked about their plans for sustainable packaging, 94 percent responded that they have at least begun to discuss a plan. However, less than a quarter asserted that they have a fully mature program. Download the full survey report.

The world is struggling to properly use and reuse plastics in a manner that will aid the circular economy, extending the service life of products and providing a safe and efficient system for disposal.

Traditionally, one of the biggest challenges in producing eco-friendly packaging has been the lack of sustainable materials that could be leveraged at scale. But now, material suppliers, converters and brands are experimenting with sustainable materials like post consumer resins that can compete with incumbent virgin polymers.

In our newest documentary, The Sustainable Packaging Revolution, Jabil investigates the current state of sustainable packaging solutions with a close eye on sustainable material technologies. We spoke to some of the world’s most cutting-edge sustainable material suppliers to get their perspective on where we are today and where we’re headed in the future.

Here are some of our top findings:

Getting Creative with Post-Consumer Recycled Resins

There are several methods for blueprinting a more environmentally conscious design, such as lightweighting or making packaging reusable. You could also ensure that your new design leverages a material that fits into a single polymer group making it easier to recycle. Due to some recent advances in performance and design (More color options) capabilities, we’re also seeing a significant amount of excitement around the use of post-consumer resin (PCR) in innovative new applications.

According to the Jabil survey, 47 percent of participants plan to use PCR as a pillar in their sustainable packaging strategy.

Located in Troy, Alabama, KW Plastics is the largest plastics recycler in the world. But more than being a recycling company, they are also a recycled resin pellets supplier, boasting the silo capacity and equipment to process more than a billion pounds annually.

KW purchases bales of high-density polyethylene and polypropylene, commonly known as number twos and fives, from throughout North America and beyond. It is transported to Troy, size-reduced, washed and ultimately transformed into multiple color variants of PCR that is resold for various applications.

Companies have found several ways to incorporate this resin into their packaging solutions: water bottle caps, takeout food containers, paint cans and more. And the resin isn’t just being used in packaging; because of its light weight and durability, the automotive industry has been utilizing it to make bumpers and seats. The ability to meet the stringent standards of the automotive industry speaks highly of the resin quality.

Although people are becoming well-aware of the environmental impact of plastics, fewer people are likely to recognize the economic benefits of recycling. Recycled materials are a commodity. There is a price tag associated with every piece of plastic that consumers toss into a trash can. In fact, there’s value all along the supply chain in terms of jobs and revenue. By investing post-consumer resins, companies can recapture the value of their packaging.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

Maximize the Possibility of Safe Disposal with Bioplastics

A significant challenge for the industry is not only establishing a proper recycling system but ensuring that consumers understand the system itself.

There are key differences between bio-based, biodegradable and compostable materials. Bio-based products are made from biomass, such as corn, sugarcane or cellulose, but they are not necessarily biodegradable. The term “biodegradable” refers to the chemical process by which microorganisms that are available in the environment convert materials into natural substances such as water, carbon dioxide and compost without assistance from artificial additives. However, this process is dependent on the surrounding environmental conditions (such as location and temperature) as well as the material and application.

There is a “hierarchy” of biodegradability. The more oxygen-rich the environment is, the easier it is for a package to naturally break down. Industrial or home composting affords the cleanest decomposition due to the controlled nature of the environment and the large amount of bacteria that can surround and degrade the polymer. The lack of suitable bacteria in marine water makes it the most difficult condition for plastics to degrade.

Thankfully, consumers are becoming more aware of the problem. But even well-intentioned buyers who purchase bio-based or biodegradable products often fail to fully understand the terminology and subsequent end-of-life process, incorrectly disposing of products, assuming they will organically dissolve into an eco-friendly mass.

The reality is that if a package, even if it’s made of organic materials, is not disposed of through the correct channel, it can have a detrimental effect on the environment.

In fact, according to a report released by the United Nations, because of the lack of consumer responsibility, widespread adoption of biodegradable materials will not significantly decrease the volume of plastics finding their way into the ocean or the physical and chemical risks that plastics pose to the environment.

There are improvements that can and should be made to the current recycling and waste disposal infrastructure. But in the meantime, companies like Danimer Scientific, a biotechnology company, are collaborating with brands to create compostable or biodegradable plastic that ease the disposal burden on the average consumer.

One of the biggest breakthroughs they’ve had is the development of polyhydroxyalkanoate (PHA), a polymer that starts with natural canola and eventually returns to the earth. It will even degrade in the ocean; Danimer was the first company to ever receive a certification for marine biodegradability.

The PHA creation process is, essentially, fermentation. It starts with soil bacteria, which is fed canola oil. The organism manufactures PHA in its cells through photosynthesis. It then ferments, fattens and multiplies. Once the vessel is full, Danimer extracts the stored energy from the bacteria. The resulting polymer is marine biodegradable and industrially compostable, indicating a large, multi-step change in terms of possible capabilities.

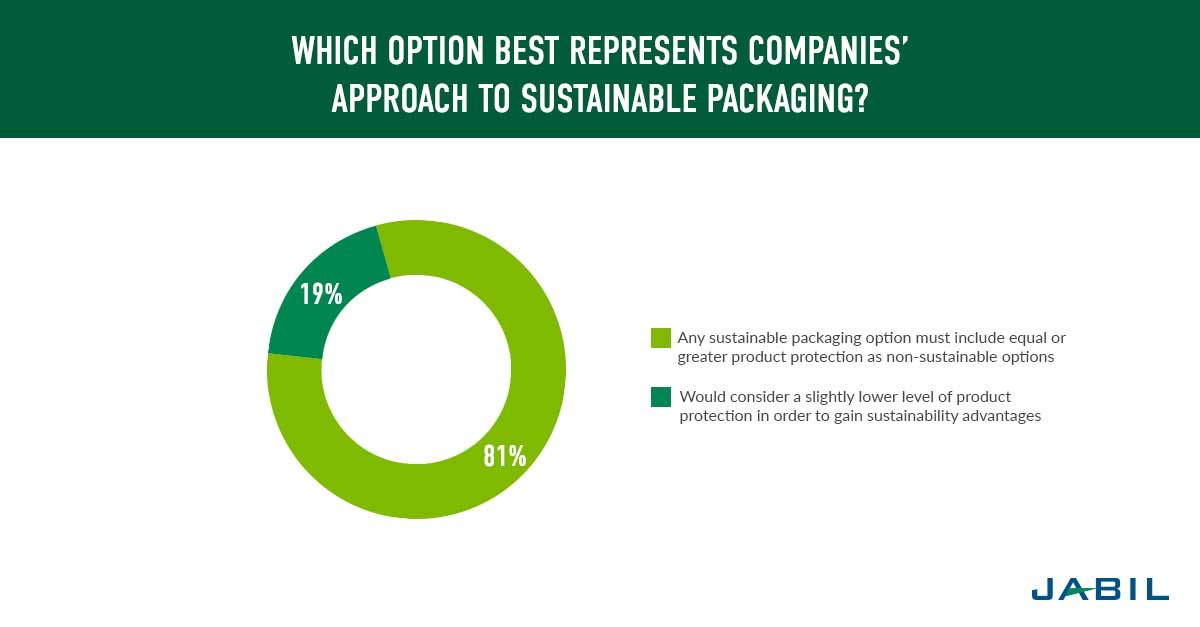

It can be challenging for brands to find a bio-based or biodegradable solution that is also high-performing. However, PHA has received FDA approval, an important factor for food and beverage companies that are dedicated to protecting their goods from damage or contamination. In Jabil’s survey, 81 percent of participants responded that they are unwilling to sacrifice quality for sustainability, especially food and beverage brands, which potentially face disastrous consequences if their product becomes contaminated. FDA-certified sustainable solutions promise a step in the right direction.

The creation of a bio-based, biodegradable plastic that can meet government regulations is a significant step forward for sustainable solutions. But it will take more than one strong solution to achieve a circular economy and ensure a more sustainable future.

Collaborate to Develop a Circular Economy

A circular economy is one that maximizes the service life of each individual product while minimizing its effect on the environment. It isn’t a singular, isolated endeavor; it involves everyone. Recycling facilities need to optimize their processes to ensure minimal waste; brands and packaging converters must design their products for sustainability; consumers should make a concerted effort to put their waste through the proper channels of disposal; and governments need to support these efforts through robust infrastructure and incentives.

This is a highly complex issue, and it is not within the scope of any individual or organization to rectify it. Developing and producing sustainable solutions will require consistent, global effort on the part of corporations, individuals and governments. Even when compared to other transformational industry shifts such as child-resistant packaging, the scope and magnitude of sustainable packaging stands alone.

Working with global brands to develop new packaging solutions, Jabil leaders have noticed a significant shift in the mindset and commitment from packaging leaders around the world. And this enthusiasm at the corporate level is now being matched by consumers that are willing to accept prices or aesthetics that are different from the current solutions. We’ve also seen companies setting internal sustainability goals and developing strategies to reach those goals. And converters like Jabil are aligning with material suppliers and the rest of the value chain to help brands meet their sustainability goals.

At Jabil, we follow the traditional “reduce, recycle, use” approach to sustainability, but we believe there is also a vital fourth element: rethink. Rethinking packaging requires visibility and information throughout the entire supply chain and manufacturing process. Companies aiming to create more sustainable packaging solutions need partners who will optimize designs for sustainability, iteratively and rapidly assess the carbon footprint and determine the best material selection and sourcing options to help brands achieve their goals.

It is daunting, but achieving the circular economy is not an unrealistic goal. The sustainability initiative is more complicated than a change in mindset, more impactful than just improved recycling rates and bigger than individual, siloed efforts; it’s a world-shaking revolution.

Download the Sustainable Packaging Trends Survey Report

Insights from over 200 packaging decision-makers at global enterprises on their sustainable packaging goals, initiatives and challenges.