Our History

Jabil’s cultural DNA is rooted in our humble beginnings.

Ingenuity and Early Success

From the beginning, the world’s leading brands have trusted Jabil to help them make

their products possible — and make them better.

’60s

1966

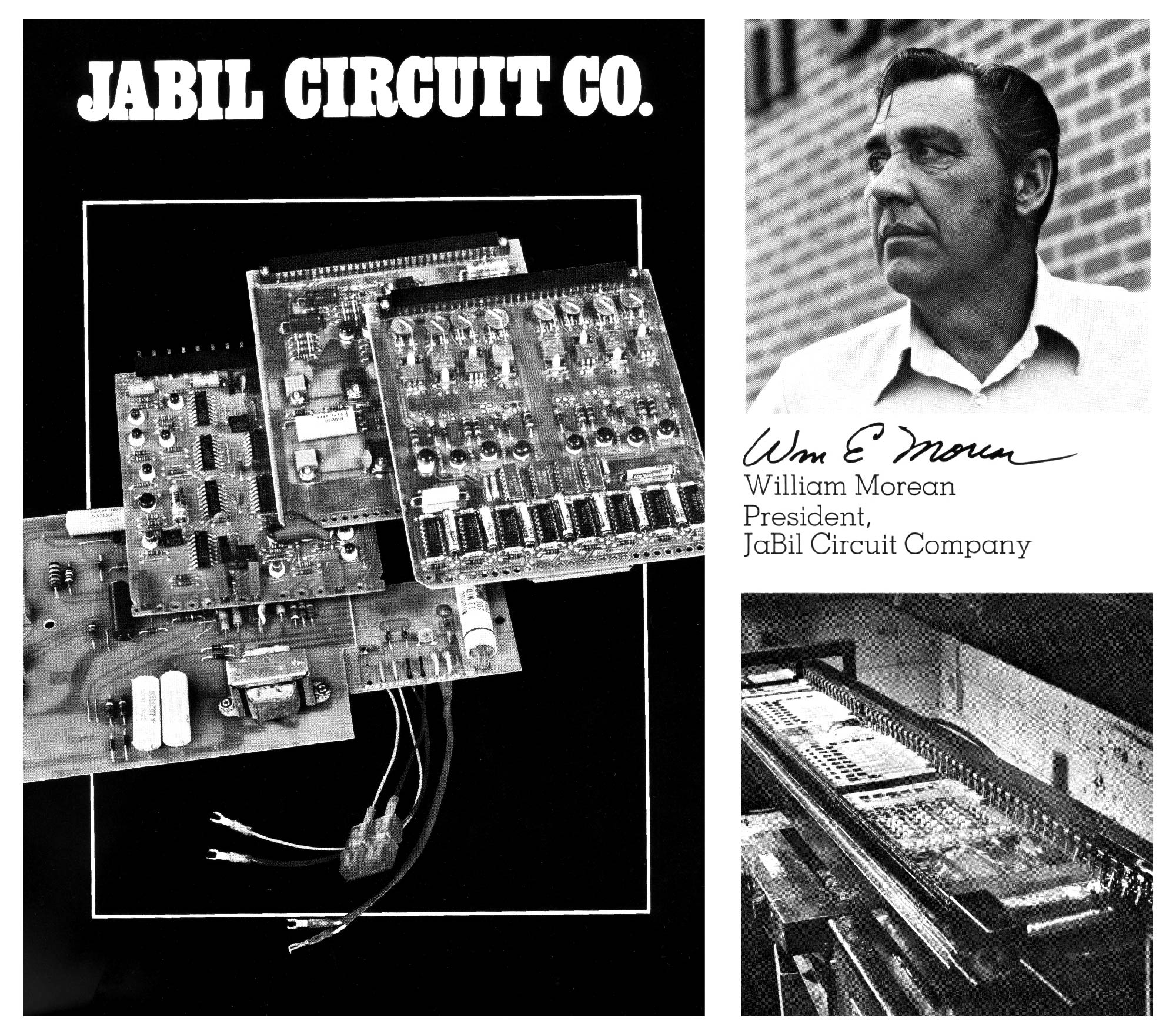

James Golden and William Morean enter a 50-50 partnership as Jabil, a fusion of their first names.

The company starts out building circuit boards on the kitchen table of the Morean home outside Detroit, Michigan, for their first customer, Control Data corporation.

1967

Jabil receives its first production order. Previously, the company only provided printed circuit board (PCB) service orders for broken equipment.

1969

Jabil Circuit Company is incorporated.

’70s

1970

Jabil wins its second customer: General Automation, a designer and manufacturer of computers primarily for auto assembly line controllers.

1978

The company moves to a 7,200-square-foot facility in a high-tech industrial area of Troy, Michigan.

1979

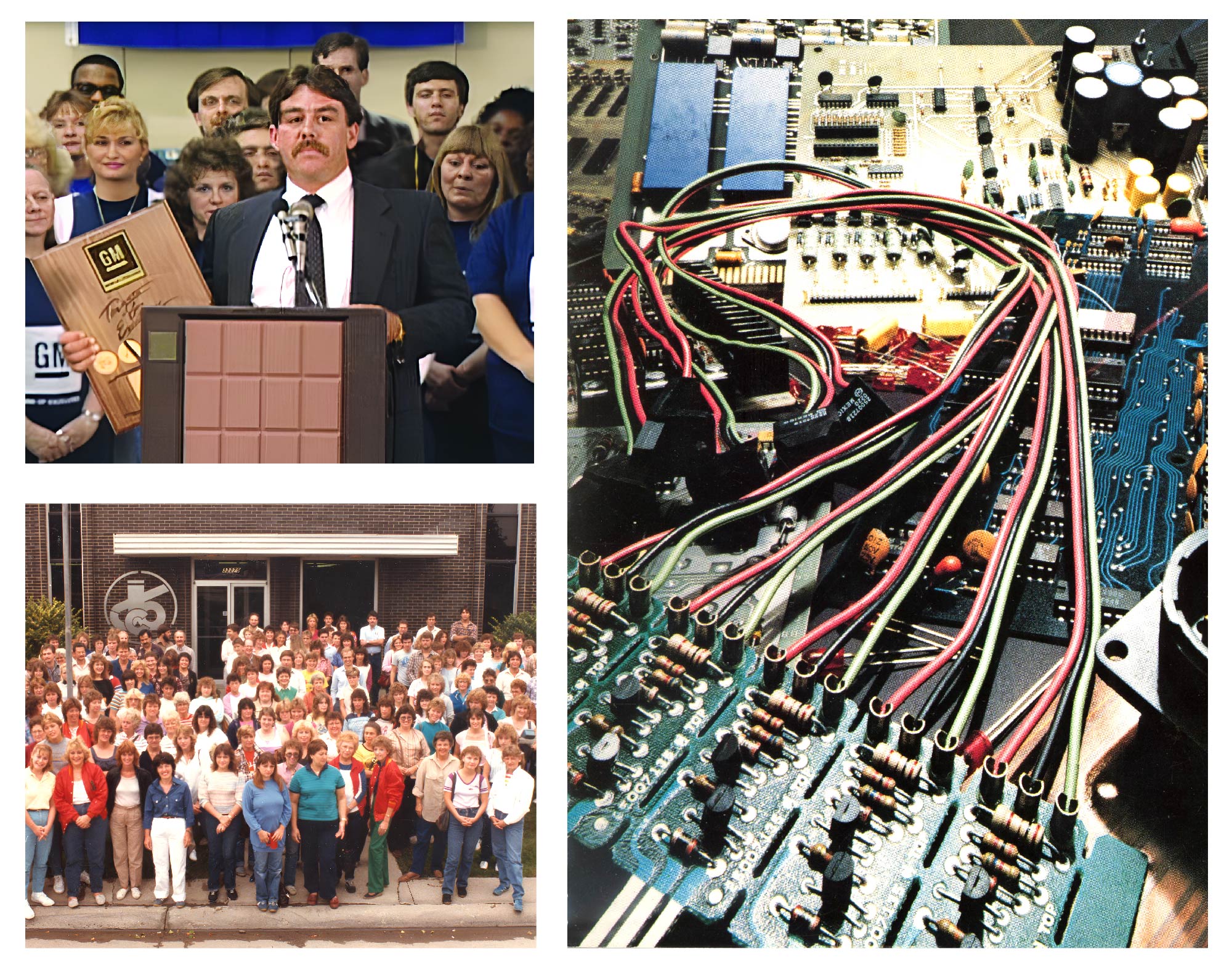

General Motors awards Jabil a $15 million high-volume PCB manufacturing contract, putting Jabil on the map and allowing the company to expand its automated assembly capability.

’80s

1982

General Motors engages Jabil to help with a redesign of the Corvette's dashboard display. Jabil manufactures a component that powers the LCD display in the new car model.

Jabil’s headquarters are relocated to St. Petersburg, Florida.

1985

After investing in newly developed surface-mount technology (SMT), Jabil begins highly automated volume production of circuit boards using SMT processes.

1987

Jabil establishes a prototype and design facility in San Jose, California, to research and test commercially promising technology, most notably SMT.

1989

Jabil launches its box-build operation, encasing motherboards in plastic. This marks the company's first step towards complete assembly solutions.

“I’m sure my dad would be amazed to see the cultural values of accountability and empowerment intact in the global powerhouse that Jabil has become.”

’90s

1993

Jabil opens its first international site in Scotland to provide service to customers with operations in Europe.

1996

Jabil expands into Asia with a factory in Penang, Malaysia, which manufactures high-end disk drive product assemblies.

1999

Jabil acquires Hong Kong-based GET Manufacturing, Inc., adding 1 million square feet of manufacturing capacity worldwide and an additional 5,000 employees.

Expansion and Continuing Innovation

Jabil combines its growing global reach with local expertise to deliver customized manufacturing, engineering, and supply chain solutions while building sustainable processes for the generations to come.

’00s

2001

Jabil announces plans to enter the fiber optics market and increase manufacturing capacity. A technology services division is created, complete with an optics lab.

2002

Jabil launches into the defense and aerospace market with work on guided missile electronics, night vision sensors, and aircraft radar systems.

2004

Jabil opens a 175,000-square-foot facility in Pune, India, providing a full spectrum of services for instrumentation, networking, peripherals, and telecommunications.

2007

Jabil purchases Taiwan Green Point Enterprises Company, Ltd., a state-of-the-art plastics and metals manufacturer. This adds nine factories and 30,000 new employees.

Jabil is the first company of its size in the world to attain ISO 9000 quality certification.

2009

Jabil makes Newsweek's inaugural Green Rankings list, an environmental ranking of the top 500 largest publicly traded corporations.

“Change and renewal has been a very important part of our story from the beginning. We’ve transitioned from a ‘board stuffer’ to a ‘solutions provider,’ from a company heavily concentrated in the communications sector to a balanced and diversified global manufacturer… We believe continuously improving what we do, with the same systems and values around the world is key to building strong, long-term relationships.”

— TIMOTHY MAIN, PRESIDENT AND CEO (2000–2013), CHAIRMAN OF THE BOARD (2013–2021)’10s

2011

The company begins construction of a new injection-molding factory in Shenzhen, China, to provide medical device manufacturers with cost-effective manufacturing services.

A new photovoltaic laboratory in St. Petersburg, Florida, opens. It provides Jabil with a range of UL and IEC photovoltaic certification and testing capabilities that support the company’s manufacturing sites and its solar equipment customers.

2012

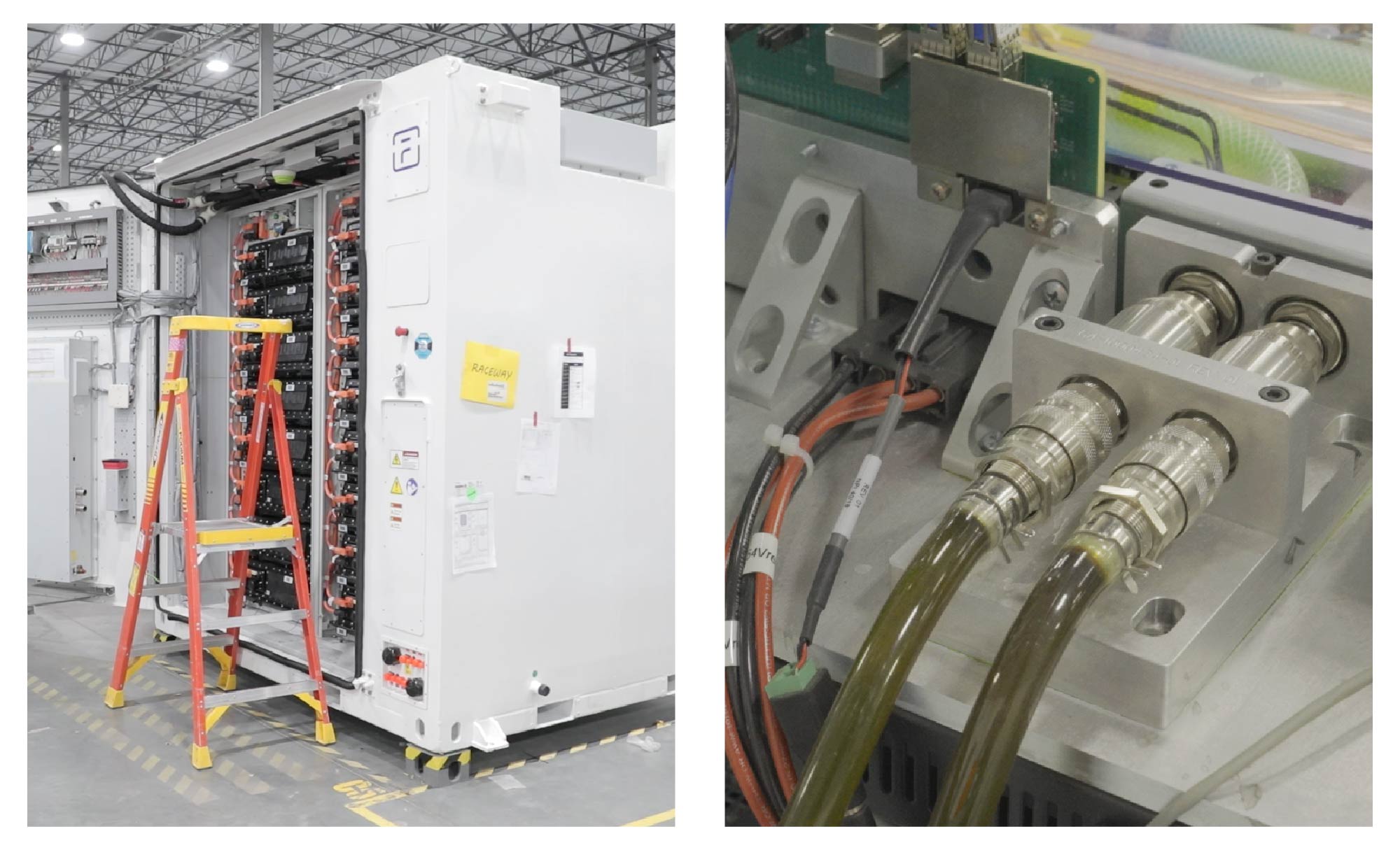

Jabil enters the electric vehicle (EV) market, leveraging decades of experience in automotive and electronics to build EV powertrains, charging components, and more for some of the world’s leading brands.

2013

Nypro, Inc. is acquired. The acquisition brings expanded capabilities in customer packaging across several industries and more than 10,000 additional employees.

2014

To meet the needs of a data-driven world, Jabil establishes its cloud data center business. This initiative is part of Jabil’s efforts to diversify revenue amongst its business units.

2017

Jabil operates in over 100 locations across more than two dozen countries. It is the world's third-largest manufacturing solutions provider.

2018

As part of a strategic collaboration with Johnson & Johnson Medical Devices (JJMD) Companies, Jabil acquires 14 JJMD sites across the Americas and Europe. The acquisition adds new capabilities for the production of orthopedic and minimally invasive surgical devices, making Jabil the largest healthcare manufacturing solutions provider in the world.

Jabil scales its renewable energy business through partnerships with companies producing solar energy equipment, wind turbines, and intelligent grid management systems.

“I think of going from our founders the Morean family, and their kitchen table in Michigan, to a Fortune 200 company and I think to myself, ‘That’s the kind of stuff that books and movies are made of.”

’20s

2022

Jabil scales its energy storage system business with the opening of its site in Salt Lake City, Utah.

2023

Within the cloud business, Jabil shifts its focus to artificial intelligence-powered cloud data centers, enabling the next generation of technologies.

Jabil divests its mobility business to BYD Electronic (BYDE), with sites in Chengdu and Wuxi, China, transferring to BYDE. This divestiture is intended to better align Jabil’s technologies and capabilities with the future needs of its customers.

2024

Jabil acquires liquid cooling solutions provider Mikros Technologies to expand the company’s data center infrastructure capabilities.

2025

Jabil acquires Pharmaceutics International, Inc. (Pii) to bolster its existing portfolio of pharmaceutical solutions.

2026

Jabil marks its 60th anniversary and grows its data center power management capabilities with the acquisition of Hanley Energy Group.

“As the geopolitical situation continues to evolve, our ability to adapt, combined with our designation as a U.S.-domiciled manufacturing service provider and our global footprint, is becoming increasingly important for our customers. And in my opinion, Jabil is among the best-positioned companies in the world to help customers navigate these complexities.”

Learn more about our global footprint

Our Locations