Case Study

Advanced manufacturing and technical solutions for the world’s leading healthcare companies

At Jabil, the patient is at the center of everything we do.

For over 20 years, the world's leading healthcare companies have put their trust in Jabil and our foundational, patient-focused quality culture. We are now the largest manufacturing solutions provider serving the healthcare industry.

Jabil's award-winning, purpose-built facilities span the globe, delivering unparalleled scale, and executional excellence to our customers. Together, we are reimagining new and better ways to improve how people experience healthcare, ensuring continuity of care, and helping people to live longer, healthier lives with greater ease and independence.

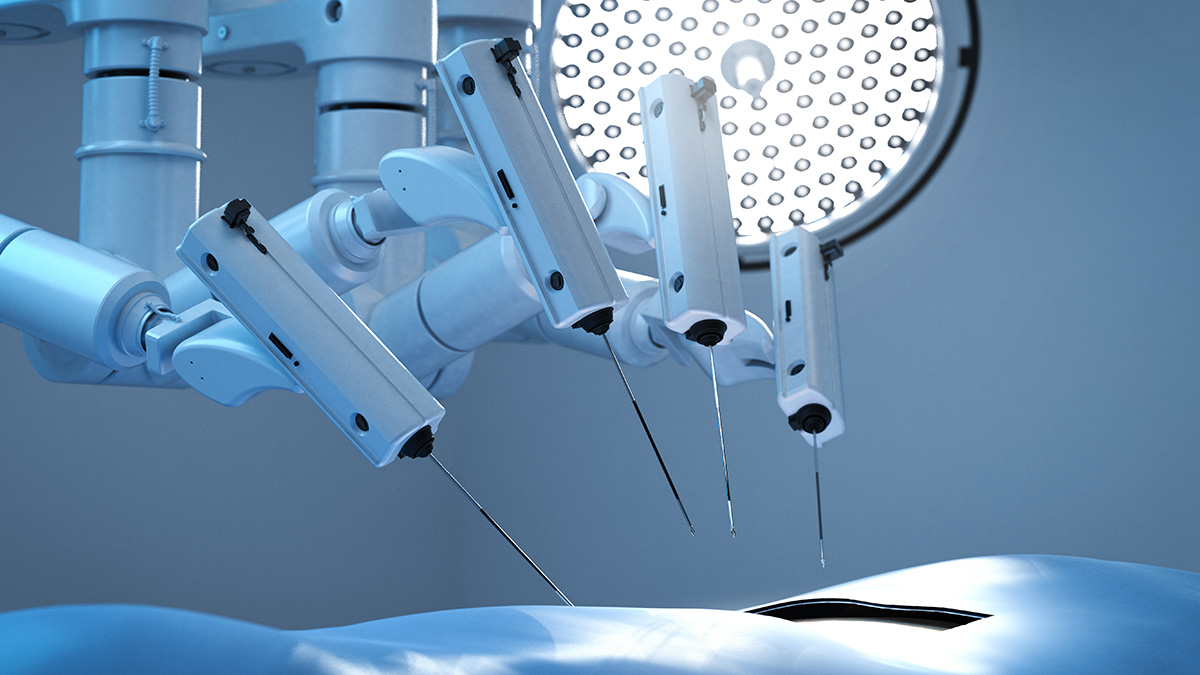

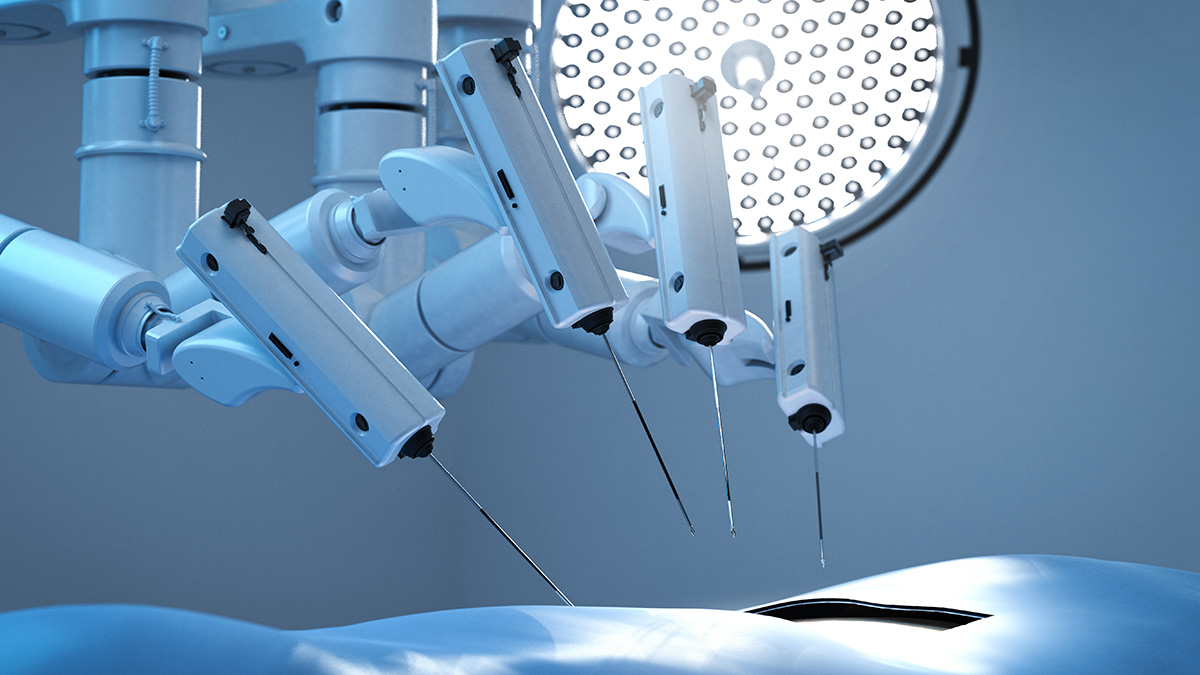

Comprehensive and technically sophisticated manufacturing capabilities across medical device, instrument, and capital equipment domains, including minimally invasive devices (MID), robotic assisted surgery (RAS), complex catheter, diabetes care, patient and chronic disease management, medical aesthetics, consumer health devices, and more.

Offering an unmatched suite of experience, capabilities, and capacity for the manufacture of orthopedic implants and surgical instruments within spine, trauma, and craniomaxillofacial (CMF) markets.

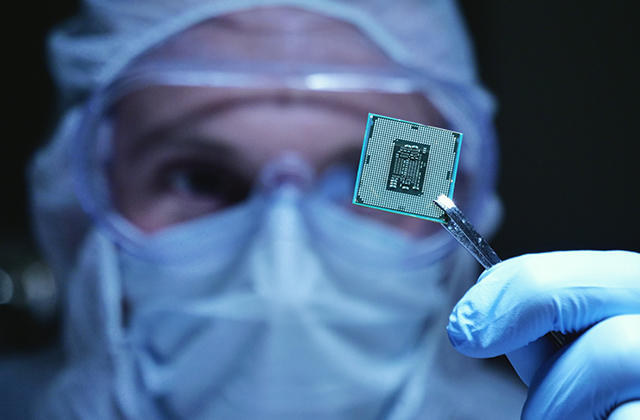

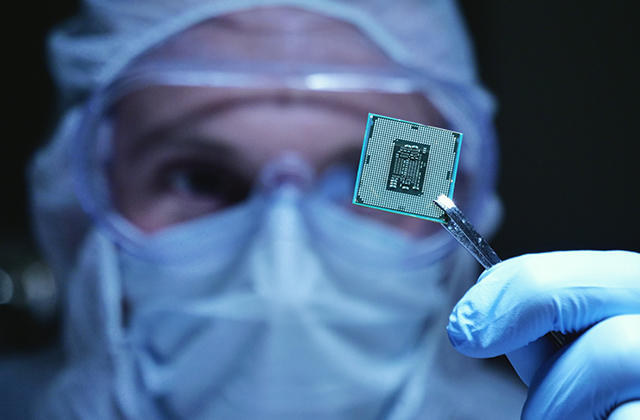

Technologically advanced and comprehensive capabilities spanning diagnostics and life sciences applications, including diagnostic imaging capital equipment, instruments and consumables for central lab, molecular point-of-care (POC), genomics, and other market segments.

Every year, Jabil is trusted to deliver hundreds of millions of drug delivery devices for leading pharma brands. Our recent acquisition of Pii, a CDMO, means that we can deliver true end-to-end pharmaceutical solutions, from drug development and device design to commercial manufacturing with aseptic fill/finish and packaging.

Manufacturing partnership across the product lifecycle

Based on the global markets and diverse industries we serve — including more than five decades of consumer electronics experience — Jabil offers unmatched intelligence and insight for customers addressing both healthcare's complex regulatory requirements

and increasing speed-to-market challenges.

Jabil’s expertise covers every phase of the innovation cycle, from discovery and planning to design, development, manufacture, and post-production support, including industry-leading supply chain stewardship, product lifecycle management, and post-market surveillance.

Commercialization capabilities and services for regulated market success

Trust Jabil to deliver on stringent process requirements across a range of specialized technical services for the changing face of healthcare.

At Jabil, our leading Quality Management System (QMS) and regulatory compliance expertise define not just what we do, but who we are — reinforcing our goal to be a safe pair of hands for our customers and their patients.

Our healthcare manufacturing sites operate within Jabil’s global quality management system to ensure consistency across our worldwide manufacturing network. Jabil’s QMS complies with domestic U.S. regulations, as well as with UL, CSA, TÜV and other global regulatory bodies. Jabil has received the renowned Shingo Prize at two sites — Bray, Ireland, and Shanghai, China — for operational efficiency and excellence.

Numerous Jabil healthcare sites have been awarded prestigious MedAccred® accreditation, for manufacturing processes such as printed circuit board assembly (PCBA), plastics injection molding, plastics mechanical assembly, and electronics manufacturing. Each of our factories producing finished medical devices are registered with FDA and hold QMS certificates. Including:

ISO 13485

21 CFR Part 820

21 CFR Part 11

21 CFR Part 4 (select sites)

ISO 14971

ISO 9000

ISO 18001

ISO 14000

Strategy, research, design, technology, testing, and engineering experts, backed by Jabil’s deep manufacturing experience, will help you decide what to make and why, then help develop and scale your solution through commercialization and lifecycle management.

Jabil currently offers in-house Gamma sterilization, and we are expanding to add in-house EO and X-ray sterilization over the coming months. Our manufacturing facility in Albuquerque, New Mexico, houses one of the largest gamma irradiators in the world, and we are growing our sterilization capabilities across our footprint. Trust Jabil's experience to manage the complex regulatory and supply chain challenges — and capacity constraints — of this critical node in your healthcare manufacturing operations.

Jabil's medical device reprocessing operations are located across three separate facilities in Maple Grove, Minnesota, an hour northwest of Minneapolis. Reprocessing brings new life to medical devices and components, saving as much as 50% on overall device expense while reducing both landfill waste and disposal costs. As healthcare OEMs increasingly prioritize both value-based care and sustainability objectives, the work done at Maple Grove is a vital win-win towards achieving a more circular economy in healthcare.

Additive manufacturing materials and processes provide practical, strategic value within the medical sector. The process enables rapid prototyping rounds and can help reduce costs related to assembly, warehousing, and supply chain management.

Jabil’s regional manufacturing network solutions lower customer costs by spreading labor intensive manufacturing and assembly steps across our integrated network of best-in-class sites.

Get started with a trusted partner.

Case Studies

Articles & Blog Posts

NEWS

Apr 04, 2025

NEWS

Apr 02, 2025

NEWS

Apr 02, 2025

NEWS

Mar 25, 2022

Insight

Insight

INSIGHT

NEWS

Apr 04, 2025

NEWS

Apr 02, 2025

NEWS

Apr 02, 2025

NEWS

Mar 25, 2022

Insight

Insight

INSIGHT

Announcements

NEWS

Feb 21, 2025

NEWS

Feb 04, 2025

NEWS

Mar 07, 2024

NEWS

Apr 13, 2023

NEWS

Sep 04, 2023

NEWS

Oct 27, 2021

NEWS

Feb 21, 2025

NEWS

Feb 04, 2025

NEWS

Mar 07, 2024

NEWS

Apr 13, 2023

NEWS

Sep 04, 2023

NEWS

Oct 27, 2021