The Convergence of Design and Manufacturing: A New Era for the Development of Automotive Optics

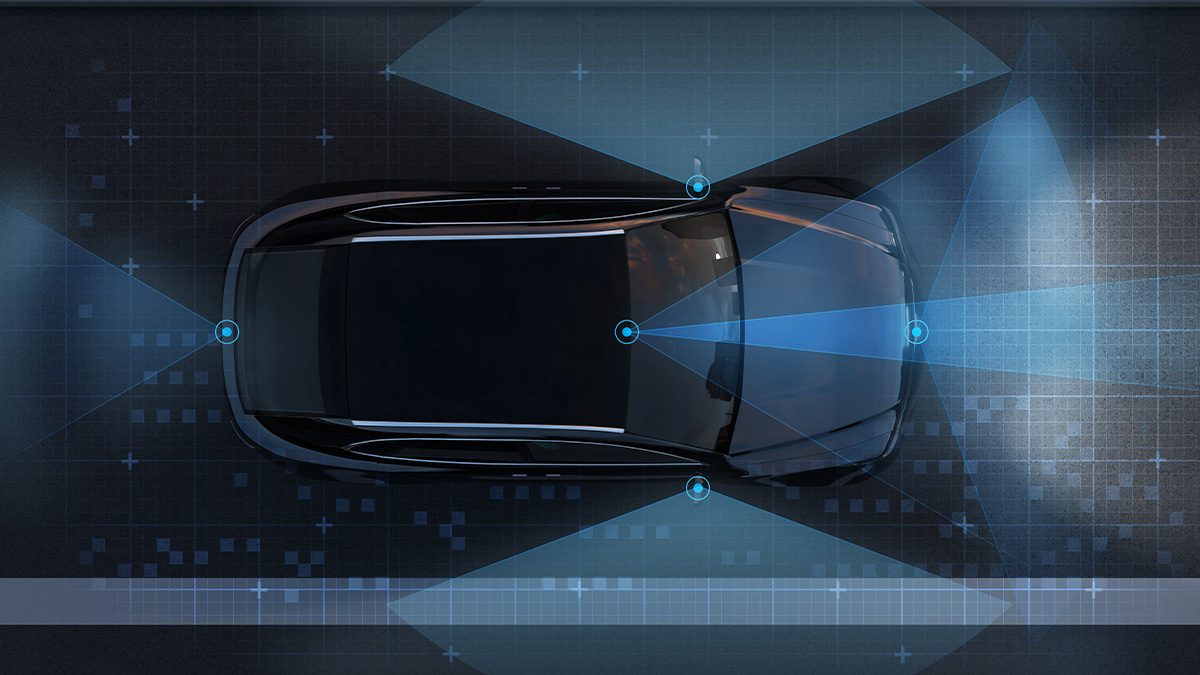

With the increasing number of advanced driver assistance systems (ADAS) and automated safety features on vehicles, there is a skyrocketing demand for sophisticated and highly accurate optic-based systems, such as ADAS, cameras, and LiDAR. These systems enable functions such as lane-keeping technologies, emergency braking, adaptive cruise control, and blind spot detection — taking us further along the journey to full vehicle autonomy.

A 2023 report from McKinsey estimates that the value of ADAS and the autonomous-driving hardware market for passenger cars could reach $55–$80 billion by 2030. This is reinforced by the estimate that passenger cars will be built with at least five cameras by 2030, up from the approximately 2.5 cameras installed on cars built in 2023 (based on TechInsights’ February 2024 ADAS Forecast).

However, mass adoption of these technologies is a huge undertaking and presents many new challenges to the industry. For one, the optics used in ADAS technology are rapidly increasing in sophistication. ADAS systems are often safety-critical — especially at higher ADAS levels (level 3 and 4). Their failure could have a catastrophic impact on a vehicle and its occupants. These new optics technologies must be designed and manufactured to the correct industry Automotive Safety Integrity Level (ASIL).

Automotive systems, from backup cameras to airbags, typically receive an ASIL risk classification following the ISO 26262 standard. The rating combines risk exposure, controllability, and failure severity. Higher safety ratings require a design and manufacturing approach to meet quality standards, customer requirements, and safety regulations. Strategic partners who have expertise in automotive functional safety can integrate safety considerations from the initial stages of product design and reduce non-compliance risk.

Functional safety ratings for current vehicle vision and ADAS systems that leverage optics are generally low, as drivers still largely maintain control of their vehicle even while using automated features. However, as the automotive industry evolves and reliance on sensors increases, we expect these safety ratings to rise.

New features also present new design considerations. Automotive optics technologies must be designed and built for their specific environment and operating conditions — such as extreme hot and cold, pelting snow and ice, heavy rain, and dense fog.

Additionally, manufacturing newer ADAS technologies requires new types of equipment, processes, and skilled labor. A report from McKinsey suggests that development and validation costs for highly automated Level 3 and 4 ADAS technology could exceed $1 billion per system, prompting many OEMs to seek the most cost-efficient and reliable solutions for product development.

Moreover, these newer technologies lack tried-and-tested manufacturing solutions, and best practices for their implementation are not yet commonplace. As a result, production solutions for these new ADAS and connected technologies often develop alongside the products themselves. Meanwhile, product lifecycles are shortening, sustainability is becoming an increasingly vital consideration, and the dynamics of the global supply chain are growing more complex.

To meet the challenges posed by rapid timelines, cost, and the need for custom, durable solutions, OEMs and ADAS suppliers might consider an approach to automotive optics development: working with a single-source partner who can merge design and manufacturing at scale from the beginning of the product lifecycle.

EMS Providers: One Partner to Design, Develop, and Manufacture

An EMS provider like Jabil is well-versed in automotive technologies, optics, plastics, and electronics. They can be a true partner to OEMs and ADAS suppliers — offering integrated optics solutions on a global scale.

By joining forces early in the product lifecycle, OEMs and their manufacturing partners or ADAS suppliers have the chance to align on the priorities and challenges that new technology brings to the key areas of design, supply chain, and manufacturing from the outset. The earlier that partners are brought in to plan for these three elements, the better equipped OEMs are to successfully launch these products within their desired timeframe.

This approach ensures that the designs are inherently manufacturable, identifying the processes, equipment, and talent that will be needed early in the product lifecycle to save time and money. Costs can be quickly identified and removed during the design phase.

How Do EMS Partners Help Automotive OEMs and ADAS Suppliers Get Ahead?

The integration of new optics technologies into automotive applications is a complex process. Jabil’s decades of experience designing, developing, and producing optical solutions for highly regulated industries have shown that true strategic partnerships can overcome its challenges — allowing for more innovation, faster iteration, and cost reductions.

Through this collaboration, OEMs and ADAS suppliers get a more holistic view of the product lifecycle from the very beginning and can proactively align their optics technologies with the requirements of emerging automated driving features. Here are the four areas where a strategic partner can have the greatest impact on a successful product launch.

1. Design for Manufacturing

One of the strongest value propositions of any EMS provider is their expertise in design for manufacturing (DfM). This is the process of designing or engineering a product to optimize the required manufacturing processes — improving quality and costs while making the overall manufacturing process more efficient.

This type of integrated design, engineering, and manufacturing process is incredibly valuable for automotive optics, starting with the creation of a cross-functional team that will bring the product from concept to production. It requires several areas of expertise that live within a single EMS provider, including engineering; equipment design and manufacturing; test development; and process and system development, particularly active alignment.

Integrating these functions not just at one time but also under one roof presents a unique proposition. Rather than coordinating with multiple companies, customers can work with one strategic partner who manages every element of the process, from coordinating talent to procuring materials.

Furthermore, EMS partners can manufacture at scale — allowing for the creation of technical solutions that yield more consistent results, such as with camera modules. Having product design and process development completed at the same time by members of a cross-functional team means the manufacturing equipment and processes are designed to provide higher image quality and high yield in a mass production environment.

Staying with the example of camera modules, using active alignment on equipment that was configured exactly for the specific module ensures consistent output — eliminating the need for sorting based on module performance levels. By being intimately familiar with the optical product design from the beginning, team members responsible for equipment and manufacturing processes can ensure they function effectively before production starts so all units meet the desired performance level.

The integration of the camera modules into higher level sub-assemblies is another area of expertise, and key advantage, that comes from working with EMS partners. The higher-level assembly leverages capabilities in electronics, mechanical enclosure design, tooling, and plastics that, when coupled with a developed and robust supply chain, provides support for developing unique solutions to satisfy different system requirements.

With process, equipment, and product development all working in synergy, many challenges that could arise during optics manufacturing can be effectively prevented before they happen.

2. Design for Testing

Thorough testing is critical to ensuring the quality and reliability of a final automotive optics product. Converging design and manufacturing creates an important opportunity to determine a robust but efficient test strategy for automotive optics based on their specific design, materials, and construction. Manufacturing partners do this through design for testing, an approach to design that considers testability (including how, when, and how much) throughout the entire design process.

Without this strategy, there could be time and manufacturing resources wasted to accommodate unnecessary tests after manufacturing. A lack of an effective optics testing strategy can also result in the opposite problem: quality escapes, where faulty products pass through the quality control process undetected.

3. Design for Supply Chain

In the automotive industry, a robust global supply chain that is well-aligned with design and production needs is a major success factor.

A partner who can apply their supply chain expertise to design and manufacturing planning helps make design for supply chain (DfSC) possible. DfSC involves understanding the implications of product roadmap decisions and avoiding components that pose a high risk — such as obsolescence or disruption in transit. This knowledge comes from dynamic, customized risk assessments conducted during the early design and prototyping stages, considering component and material availability, complexity, delivery, and other global factors. This approach helps to reduce vulnerability and ensure continuity in an organization’s supply chain.

The supply chain and procurement teams at strategic partners like Jabil offer supply chain expertise, market intelligence, and sourcing strategies that OEMs and ADAS specialists can take advantage of to meet production demands. For example, a strategic partner can help OEMs select components and materials early by vetting suppliers, enabling stable sourcing, and optimizing costs. They can leverage their collective spend and already-established supplier relationships to secure lower prices and potentially better lead times. These critical relationships can be key advantages for OEMs and ADAS specialists, assuring supply of high-quality parts — especially during periods of scarcity.

Having a strategic partner who can develop both the prototype and mass production supply chains creates a smooth transition between the two when it’s time to begin full-scale manufacturing. Thinking specifically about optics for automotive, Jabil’s deep understanding of the technology coupled with our years of experience in optics has enabled us to develop a specialized supply network that is difficult to match.

Partners with global reach are well-placed to gather supply chain diagnostics and provide actionable insights across the supply and demand network. This information assists not only in times of crisis but also helps improve sourcing strategies and facilitates collaboration with suppliers from the beginning of product design.

4. Domain Expertise of an EMS Provider

Supply chain expertise is just one area in the product development lifecycle in which strategic partnerships with EMS providers can provide skills, knowledge, and talent outside of an automotive OEM’s core competencies. Leveraging the domain expertise of a partner enables the OEM and ADAS supplier to consolidate the overall value chain and minimize design partners. For instance, Jabil has expertise in designing lenses that benefit our customers, with improved athermalization and transparency with the design compared to options from many vendors.

Strategic partners have expertise in not just individual technologies but also in how they apply to particular industries. For example, at Jabil, we not only know how to design and manufacture optics technologies, but we also know how to design and manufacture optics technologies specifically for automotive applications — and everything that entails. Having a partner well-versed in regulated industries who can produce to functional safety ASIL levels is critical to your product’s success.

OEMs and ADAS suppliers can also take advantage of their partners’ unique technological capabilities to solve their most pressing product challenges. For example, automotive optics technologies such as LiDAR sensors, computational cameras, and advanced projection PGUs have challenging performance requirements based on the environments in which they operate.

Particularly for agricultural optical solutions, these components must endure harsh conditions like vibration, thermal cycling, and electromagnetic interference, all while delivering high resolution and dynamic range.

Ingress protection, which measures how effectively an enclosure prevents external elements like moisture or dust from infiltrating the unit, is a key consideration for automotive optics. Given their exposure to chemicals, cleaning agents, and unpredictable weather, these agricultural solutions demand a high level of ingress protection while still maintaining optical performance.

The approach of combining the design, engineering, and manufacturing is being leveraged more with the influx of new technologies in the automotive industry. However, strategic partnerships between OEMs or ADAS suppliers and a single-source provider can enable a path forward to building the next generation of vehicles.

Collaboration is Key to the Future of Automotive Optics Technology

Working with a strategic partner to converge design and manufacturing is not just a way to build automotive optics. It’s a way to set up the industry for future success.

The convergence of design and manufacturing unlocks levels of efficiency, consistency, reliability, and quality — giving companies the advantage of time. Automotive technology is changing nearly every day; for decision-makers, getting ahead of the competition has never been so important. To do that in the face of challenges presented by new optics technologies, autonomous driving, and complex global supply chain dynamics requires innovation and agility.

Embracing partnership can provide the needed edge, driving success in the automotive optics industry. This is an opportunity to innovate, evolve, and lead in a new era of automotive transformation.

How can Jabil help you meet your automotive optics goals? Contact us.

No matter how complex or demanding the project, Jabil's automotive and transportation team is helping today’s innovators solve it. Get started with a trusted partner.