INSIGHT

Automotive electronics manufacturing that powers smart, connected mobility

Today’s passenger cars are more than just a means of transportation; they are essential to the way we live our lives. Whether used for daily commutes, school runs, or luxurious long-haul travel, there must be no compromise when it comes to safety and reliability — especially when we’re trusting the car with the safety of our families.

From driver assistance systems to electrified powertrains, we’re seeing cars become smarter, safer, and more sustainable than ever before. At the foundation of this technology evolution is automotive electronics manufacturing, which enables the production of innovative systems that must meet the strict requirements of a highly regulated industry.

Jabil partners with leading automakers and technology specialists to accelerate the launch of their next generation technology to market. Our deep expertise in product design and engineering, supply chain management, and advanced automotive electronics manufacturing processes delivers the highest quality product for our customers.

Jabil’s comprehensive capabilities support every stage of the product development lifecycle — from ASIL-certified product design and new product introduction (NPI), to supply chain optimization, and automated, high-volume assembly in IATF and VDA-certified facilities.

Across these capabilities, we’re enabling automotive electronics manufacturers to integrate advanced technologies that define the future of the passenger car.

CLICK IMAGE TO ZOOM

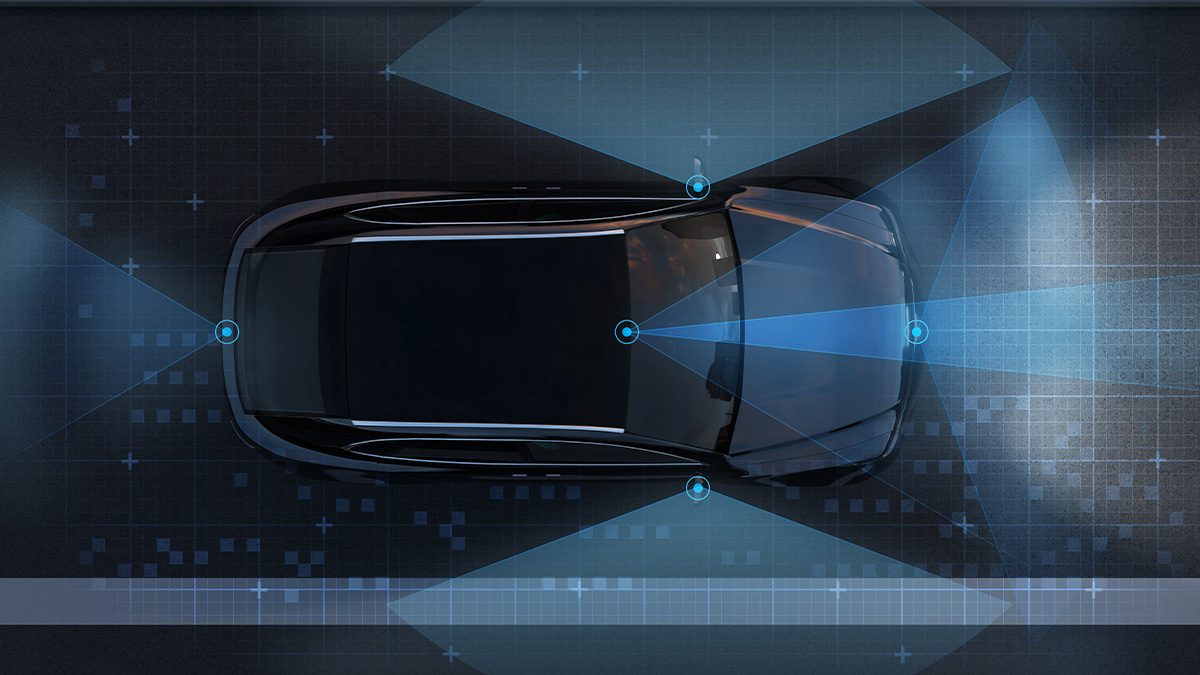

As demand for driver assistance systems skyrockets, so does the need for sophisticated and highly accurate optic-based systems, such as LiDAR, radar, and cameras. Jabil’s opto-mechanical product design and automotive electronics manufacturing capabilities, combined with our global, IATF-certified facilities, enable our customers to efficiently launch their cutting-edge ADAS technology to market.

Connectivity technologies such as vehicle-to-everything (V2X), telematics, and diagnostic dongles are transforming vehicles into dynamic, software-driven platforms. Jabil supports automakers and technology specialists in bringing these advanced systems to market with precision and efficiency. We offer world-class automotive electronics manufacturing solutions that ensure high-quality, scalable connectivity technologies.

The shift to hybrid (HEV), plug-in hybrid (PHEV), and battery electric vehicles (BEV) requires automotive-grade power and charging technology that meet stringent regulatory and consumer expectations. Battery management systems (BMS), inverters, converters, and on-board/off-board chargers require complex production processes to support global electrification efforts. Jabil’s automated assembly in advanced IATF- and cleanliness-certified manufacturing facilities ensure that next-generation high-power technology meet the scale and quality demands of automotive electronics manufacturing for our customers.

Driver assistance systems, powertrain electrification and cloud-based connectivity platforms are enabling cars to do more than ever before – but they also require more digital power than traditional systems. high-performance computers and zonal controllers are being used to manage this load and ensure the seamless integration and performance of software and hardware. Jabil customers benefit from our unique combination of automotive electronics manufacturing experience and high-powered compute expertise, to launch their new digital hardware to market at the highest quality and reliability.

Jabil sets the standard for automotive-grade electronics manufacturing, providing scalable, high-quality solutions for ADAS, connectivity, power and charging, and car compute technology. With more than 50 years of expertise in automotive electronics manufacturing, design, and global supply chain management, we are proud to partner with leading vehicle manufacturers and technology providers to power the future of mobility.

Contact Us.

Related Insights