Jabil offers comprehensive design and engineering capabilities with operations at over 100 sites in 30 countries. As a single point of accountability, we increase customer value while reducing risk by offering flexible, proactive engineering services. We help customers innovate and develop designs optimized for performance and manufacturability, then rapidly prototype for accelerated product introductions. Once designs are completed, we manufacture the highest-quality products and components using the latest automation and process technologies. All products are stringently validated and tested with Jabil’s proprietary, integrated methodologies. Finally, we help customers build in the right location, source the right materials, and reach target markets with intelligent, digital supply chain solutions.

Sign Up for Blog Updates

ENGINEERING SERVICES

MADE BETTER WITH:

-

Advanced Mechanical Engineering

-

Conceptual Engineering

-

Engineering

-

Health Engineering

-

Value Engineering (VAVE)

Advanced Mechanical Engineering

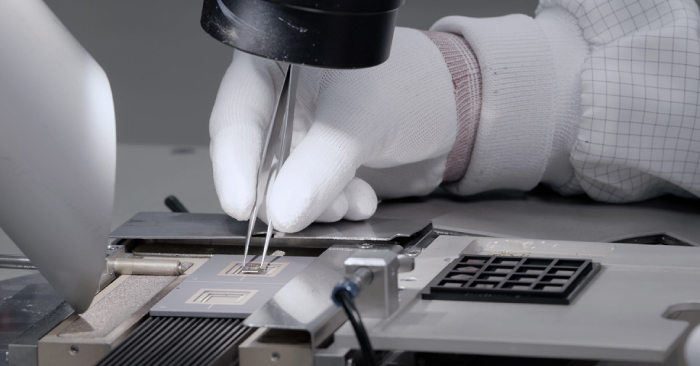

Advanced mechanical engineering solutions help build solid product concepts, designs, processes and mechanical test mechanisms to ensure that quality and value are built into every product. Jabil’s advanced mechanical engineering solutions offer customers a holistic approach to product creation, ensuring the entire process is optimized to reduce risk and ensure quality. Our engineering specialists analyze the full product life cycle to optimize successful commercialization – from understanding the relationship between mechanical components, and how they should be assembled, to collaborating with other designers to establish the functions of final mechanical products. We help our customers define part requirements for products, identify tolerances for manufacturing variability and meet design objectives throughout the product lifecycle — all with the goal of reducing costs, optimizing production timelines and improving the product’s functionality.

Conceptual Engineering

Technology innovators and market disruptors know when opportunities for new products exist, but conceptual engineering gives businesses a systematic way to answer the question, “What do consumers want and need?” With Jabil’s manufacturing expertise and experience building the world’s top products, we help our customers make significant innovations early in the product development process by looking at materials and parts requirements, needed technologies, production costs, market trends, and the user experience to determine what a product needs to be successful. We work with our customers on a wide range of conceptual engineering strategies, including content strategy, breadboarding, systems architecture, experiment design, simulation, initial cost analysis, materials identification, and design for manufacturing and assembly.

Learn MoreDesign Engineering

The product lifecycle begins with design, and so does Jabil’s expertise. From design for manufacturing and design for quality to design for sustainability, we work with customers from the earliest phases of production to optimize product designs according to your goals. With Jabil’s supply chain knowledge, advanced technology and design engineering approach, customers gain a strong partner that helps accelerate the product’s time-to-market, reduce your risk and cost potential, and increase product quality and value.

Healthcare Engineering and Technology

From initial concept design to industrialization, our more than 3,000 strategy, research, design, technology and engineering experts bring a deep understanding of scientific principles and industry and domain knowledge to help accelerate the right ideas to market while reducing risk and maximizing your ROI. In nearly every healthcare product domain our experts provide strategic insights to mitigate potential product lifecycle management and technology risks, helping to ensure the most competitive profile for your products in the market.

Learn More

Value Engineering

In the evolving digital age, new technology trends and manufacturing methods require companies to keep their products and processes as efficient as possible without sacrificing quality. Jabil’s value analysis and value engineering (VAVE) services offer a proactive approach designed to increase value and decrease cost throughout the bill of materials, creating a seamless transition from design to manufacturing. We help customers save time and money by simplifying designs, reducing unnecessary parts, securing the best component pricing from the highest quality suppliers, and incorporating manufacturing and test best practices into a product design from the start. We can eliminate expensive and time-consuming fixes by proactively diagnosing component malfunctions and analyzing each design for manufacturing, supply chain and environmental compliance while conducting critical tests early in the design phase.