Industries We Serve

Delivering Value in an Era of Unprecedented Change

-

Automotive Electronics Manufacturer

World-class automotive electronics manufacturer; supplier with supply chain expertise & industry partners - strategically capitalize on technology.

-

Capital Equipment

Jabil serves the capital equipment sector with best-in-class manufacturing services. Trust Jabil to accelerate your time-to-market and market leadership.

-

Cloud Data Centers

Jabil provides a portfolio of server platforms and personalized, infrastructure delivery services for the cloud data center.

-

Commercial Truck & Bus

Connectivity, human-machine interfaces, and smart safety systems are a must for agriculture, construction, mining, and rail industries. Ensure their strategic use with Jabil.

-

Defense & Aerospace

Aerospace and Defense - Jabil specializes in mission-critical high-mix/low-volume electro-mechanical systems for defense OEM and military supply chains.

-

drones

Jabil can help speed your time to market by providing necessary capabilities in materials, power management, optics, sensors, molding, assembly, and electro-mechanical manufacturing. Today, Jabil provides many of these solutions to top automotive brands to support autonomous driving features which are similar to drones used in beyond-visual-line-of-sight (BVLS) missions.

-

Healthcare

Jabil Healthcare - leading the industry with execution on digital healthcare, product lifecycle management, miniaturization and additive manufacturing.

-

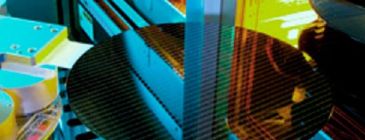

Jabil Photonics

Jabil provides quality components and services so you can streamline & accelerate the development and time-to-market of your optical communications.

-

Networking

Jabil helps our customers bring switches, routers, firewalls, hyperconverged and other networking products to market with higher quality and cost-effectiveness.

-

Packaging Solutions

Trust in Jabil’s packaging solutions expertise to deliver intelligent packaging, active packaging, rigid packaging, and consumer device packaging.

-

Printing

Jabil is a world leader in print manufacturing: pre-printing capital equipment and consumer/enterprise printers, emerging 3D printing technologies and more.

-

Renewables & Energy Infrastructure

Jabil's renewables and energy infrastructure solutions help customers to innovate products, disrupt industries, and capitalize on new market trends.

-

Retail Technology & Digital Commerce Solutions, Robotics, Automation, Payment Solutions

From the warehouse to the store, to your home, today’s retail ecosystem is being transformed by innovative technologies providing a richer, more efficient and personalized world of choice across the value chain. Jabil is uniquely positioned to help companies stay ahead of emerging trends and technologies so they can deliver exceptional, reliable solutions that meet the changing needs of their customers.

-

Smart Home & Appliance

Jabil Components Are Part of Over 40% of Today's Appliances, with Over 100 Million Assemblies Shipped.

-

Telecommunications

A total solutions partner for the telecommunications industry committed to accelerating time- to-market and maximizing return on investment for our customers.