Augmented Reality Applications: Transforming Four Industries

Without doubt, augmented and virtual reality (AR/VR) have become synonymous with the gaming industry – where consumers find the most relevant use cases. Gaming may be how augmented reality reaches the masses, but there is an unparalleled opportunity for industries to implement AR applications into their work.

In the recent Augmented and Virtual Reality Trends Survey sponsored by Jabil, only 29 percent of respondents said they had a AR/VR plan or framework at some stage of development. Contrary to the beliefs of those with no plan or pilot in place, this same group also indicated that the business or enterprise use of AR/VR would be first to become widely adopted.

Augmented reality delivers information to users while allowing them to see and interact with actual or virtual objects in unconventional ways – all overlaid onto their physical world, in front of their eyes. While the concept may sound simple, it is far from it. But the possibilities that come with AR are infinite and will transform how numerous industries function. Let's examine how four major industries will benefit from augmented reality applications:

Augmented Reality and Automotive Show Signs of Success

While autonomous cars may be the talk of the town in the automotive industry, I believe optics are one of the main drivers of advancement in this market. As we saw at CES 2018 in January, the driving experience is becoming one of greater mixed reality (MR). Cars are now equipped with cameras and environmental sensors that power Advanced Driver Assistance Systems (ADAS) and other safety and convenience features.

Some car models have had early applications of AR features in the last few years, helping the driver stay focused on the road ahead by projecting information and data onto the windshield, transparently. The heads-up displays project content such as speed, turn-by-turn directions, maps and phone alerts for the convenience (and safety) of drivers. As these AR applications quickly advance and become standard features in cars, they will build a better automotive experience on the road to autonomous driving. The automotive industry is certainly poised to become one of the largest advocates of AR toward mass adoption of the technology. AR features will soon be a requirement for consumers in the market for a new car.

But the benefits of augmented reality extend far beyond consumer use in the automotive industry. From a manufacturing perspective, AR can be utilized to streamline the design process leading to faster product development and launch cycles. In an industry where 68 percent of auto manufacturers have a go-to-market under two years (and getting faster), according to a Jabil survey, anything that can speed up time-to-market is a welcome addition in the manufacturing process.

Making Lean Manufacturing Possible with AR

Speaking of manufacturing, augmented reality has further applications in this realm. In a setting where precision and speed are key regardless of the type of product, AR can equip line workers with easily accessible visual aids and assembly instructions on the plant floor.

Like applications in automotive, AR can help the employee keep their eyes on the work itself, without having to glance or read through a static document. In fact, in addition to manufacturing AR solutions, Jabil employees in several of our factories and customer experience centers are using the technology in exactly this way. If assembly instructions need to be updated, all the work can be done digitally, in real-time. Taking things one step further, AR technology can monitor the process assembly, provide next steps and analyze for errors and defects.

The mechanism to provide technicians with repair instructions are simplified with augmented reality. Combining AR with the use of Internet of Things technologies in manufacturing parts provides a level of detail to the technician not easily accessible before. Even when a technician may require additional assistance, another employee or plant leader can view the situation from the technician’s perspective and provide direct instructions remotely. It’s all possible with augmented reality.

Augmented reality has numerous benefits in a manufacturing environment. From informing and empowering employees to providing plant leaders with real-time access to data on plant operations, AR promises big gains in manufacturing. AR can help accelerate lean manufacturing by reducing accident rates and lead time, while increasing productivity.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

Using AR to Improve Healthcare and Medical Services

Transitioning from a manufacturing plant to a hospital room, the premise may be different, but AR yields new fields of application for surgeons. In a set of procedures in January 2018 at the Imperial College London at St Mary's Hospital, researchers were able to utilize augmented reality to overlay images of CT scans with the position of their bones and key blood vessels, so surgeons could "see through" the patient's limbs during surgery. The initial experiments are showing a promising future for AR applications in surgery, helping to decrease the margin of error and time spent on certain tasks.

In addition, the development of powerful wearable technologies not only allow physicians to monitor and treat patients without being physically present, it gives expert surgeons an opportunity to interact in an operation from start to finish, remotely. This has significant implications for the medical community. Through AR technologies, an expert surgeon could guide a local doctor through the procedure step-by-step, making remote surgery possible, according to a TED Talk by Nadine Hachach-Haram.

Augmented Reality Enables More Efficient Military Operations

The concept of heads-up displays is nothing new for the military, an industry which has been utilizing some form of the practice for military aircraft pilots since the 1950s. Now, through wearable glasses and headsets, data gleaned from satellite images and drones can be overlaid onto a battlefield – providing boots on the ground with everything from mapping information to markers defining troop movements. Moreover, when issues arise, or equipment malfunctions on the field, instructions for maintenance or repair can be easily sent over to an individual ready to act.

Besides on-field applications, augmented reality can be utilized for training purposes. As recent as August 2017, the U.S. army announced a joint effort to develop augmented live trainings to better prepare and "give valuable training time back to commanders and soldiers." The concept is to leverage the latest in technology to build immersive training capabilities that can be initiated at the point of need, leading to reduced overhead, while providing a repetitive and flexible training environment.

As we mentioned above, the commonality of these technologies is clear: augmented reality is simply virtual content that intersects with our physical world. The true difference is in how this information is used to deliver real impact within each industry and improve our lives.

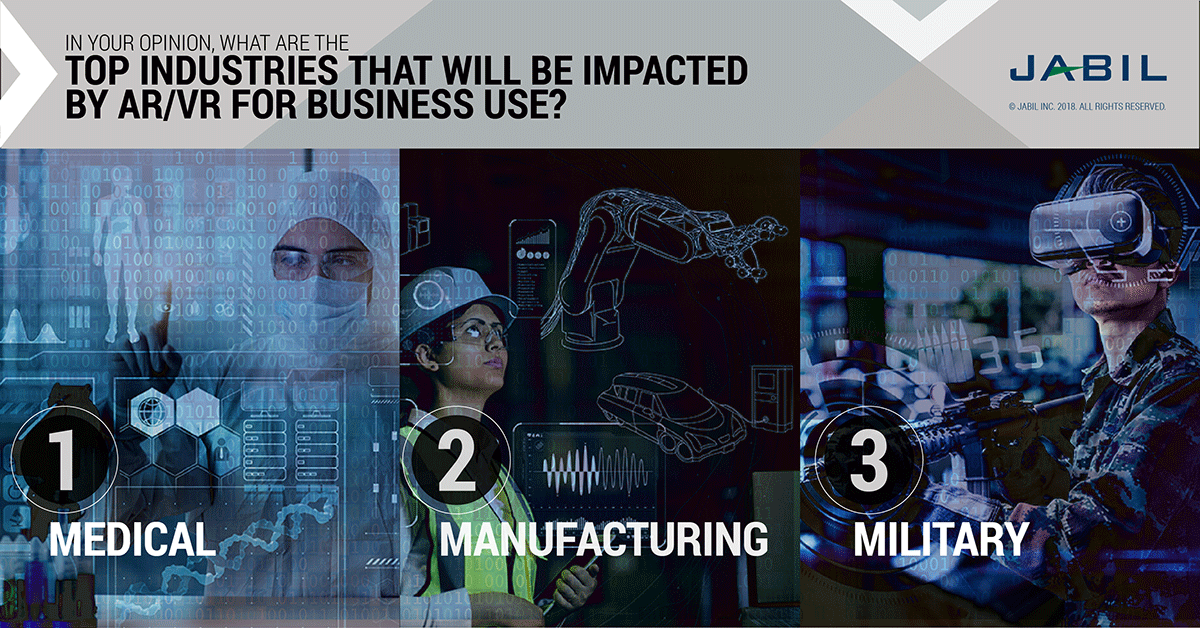

When we examine these industries from a business use perspective, Jabil's Augmented and Virtual Reality Survey respondents share that they expect medical, manufacturing and military to be most impacted from AR use.

In the current state, headsets are still bulky and existing consumer electronics just don't provide the immersive experience one can expect from augmented reality. However, as these technologies evolve with AR, it is likely that headset technologies could replace our phones and laptops, making augmented reality an immersive part of how we live and work.

Augmented and Virtual Reality Trends Report

Insights from 201 managers and executives with responsibility for AR/VR decisions at companies that design, market and/or manufacture products.