Flexible Electronics Put “Smart” in Unexpected Places

We're starting to see advanced "smart" technologies move beyond the phone in your pocket and into new areas you would not expect.

New monitoring and automation capabilities are being added to everything from cream cheese tubs to cargo containers and from the home to strategic defense, in ways that were not even conceived of a few short years ago.

More sensors and processing power are driving this revolution, but one thing is for certain: the value of technologies will have to evolve from using only traditional rigid or flexible printed circuit board assemblies (PCBAs). Flexible hybrid electronics on different substrates are the answer.

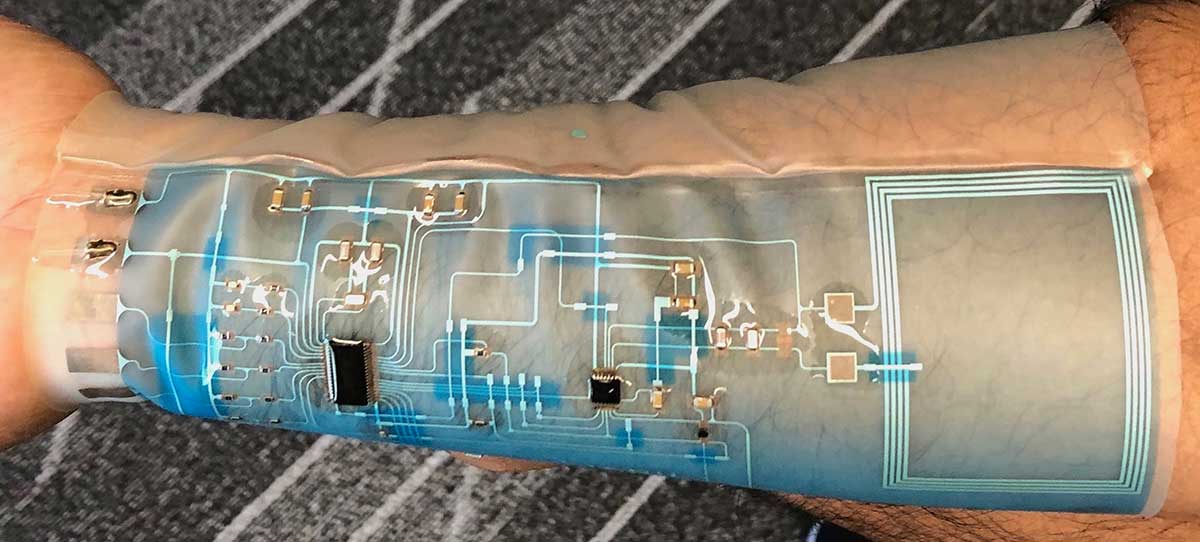

Today's smart devices are on the move, and they need sensors, memory, power, processing and communication that can move along with them. In fact, the rigidly fixed box that encloses most products' traditionally manufactured circuit boards can be replaced with flexible circuits.

Integrating flexible circuits directly on the substrates products are made of (e.g. plastic, paper or textile) opens up limitless opportunities—in everything from smartphones to medical devices like wearable heart rate monitors. This is why the printed electronics industry is experiencing its current boom.

One industry forecast predicts the flexible electronics market will grow from $31.7 billion in 2018 to $77.3 billion in 2029. While there are a lot of collaborative projects for trials and pilots to prove the business case with some winners in specific applications pulling ahead, the actual volumes as compared to traditional circuits are still low. But IDTechEX estimates that the flexible electronics connected packaging segment alone will be worth $206 million in 2025.

The reason interest is so high is the boundless potential.

Think about one of the biggest issues today in football: concussions. A combination of flexible electronic sensors and processors can monitor pressures on the head and evaluate the results of even minor impacts. Another development by the Palo Alto Research Center (PARC) uses printed biosensors integrated into a mouthguard that enables continuous sensing of lactate, glucose or other analytes.

Now, consider the same wearable electronics evolving to protect firefighters on the job by monitoring impacts or sweat. Combine that with wearable electronics that track heart rate or pulse oximetry and the use cases rapidly expand with increasing benefits derived from data. This comprehensive approach to collecting and analyzing digital health data includes monitoring of hydration, fatigue, heart rate and acoustic exposure. Because these capabilities are enclosed in a device you can wear on your wrist, it reduces the amount of weight someone with an already physically strenuous job—such as a miner or soldier—would have to carry.

Research and development in flexible electronics will see the private and public sectors in industries like aerospace each feeding the other with new capabilities. While different in end-use goals, the function of these applications will often be the same. Experience-critical data can be collected, collated and processed from a flexible circuit board to serve mission-critical and life-critical needs.

Flexible Electronics: The Right Deployment Formula

New thinking is required to develop strategies to help manufacturers effectively transition to flexible electronics while speeding deployment, streamlining operations and protecting their existing capital investment. It's necessary to evaluate the ideation of how to make a product that is thin, flexible, compliant and conformal while considering the logistics of sourcing, integrating and delivering flexible electronic components that can meet those specifications.

In the near-term, the most effective model in many cases will be a hybrid one, where an ecosystem of flexible and traditional electronic components made with both packaged and unpackaged silicon work together in a complete platform. The industry is already heading in that direction; hybrid platforms have been identified as a key trend. This will soon evolve into systems made at industrial scale, constructed out of unpackaged silicon as thin as 30um that is mounted directly to the printed traces in flexible substrates. This transition will help immensely expand the design freedom to conceive innovative products.

To maintain competitiveness, organizations also need to evaluate the performance of new emerging materials like graphene that can significantly improve the value proposition of flexible electronics.

Currently, electronics might have to be separately integrated onto a flexible material, but everyone should be paying attention to printed electronics made possible by an additive process that can produce circuits (trace), devices (transistors), components (flexible sensors) and even complete products (lab on chip).

Printed electronics technology is enabling both conductive materials such as copper and silver as well as emerging materials like graphene and organic semiconductors to be printed directly onto flexible circuits on a wide variety of substrates. These include plastic, polyurethane, textile, paper and glass. Manufacturers are utilizing multiple printing methods to accomplish this: screen printing, inkjet printing, gravure and flexography, to name a few.

Current industrialized capabilities include the ability to print high volumes of sensors—such as strain measurement devices and membrane switches—in the control panels of common appliances. Furthermore, it is now already possible to print more advanced components—such as capacitors, transistors, antennae and batteries—all on the same flexible substrate as traditional electronics.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

Flexible Electronics Applications are Almost Endless

As flexible electronics continue to refine their performance, there is a wide range of new applications on the horizon. Technology players in all industries, from healthcare to automotive to consumer electronics, will be able to leverage this ability to assemble electronic circuits by mounting electronic devices on a flexible plastic substrate. We expect the self-perpetuating development continuum to inspire ideas from big to small.

Consider a fluid-level sensor on the inside of a bottle of laundry detergent. This cost-effective sensor strip can be printed and attached to the bottle and linked to an auto-replenishment system that reorders detergent without the customer lifting a finger. But once developed, this sensor can go on to do much bigger things. For example, it could be evolved into a fleet of sensors monitoring fluid containers on an off-shore oil rig, where new deliveries can be ordered automatically when supplies are low. It could even monitor reagents in a laboratory developing antiviral medicines.

This development continuum can also include the transportation sector. Weight and space can be saved on next-generation aircraft by replacing wiring harnesses with durable strips that can mold to fuselages and bend easily around angles. Once developed, the automotive industry can benefit by replacing bulky wiring harnesses with integrated processing power to sense, energize, illuminate and establish communication in the evolving generation of electric and autonomous vehicles.

What we've seen as this field progresses are different innovators in the flexible electronics continuum that are advocating the benefits of their own technology in vertical silos. Industry established leaders, as well as new and upcoming startups, are looking to complement that with comprehensive approach to spread the benefits throughout the ecosystem and obtain a more market-ready but disruptive product. That's why Jabil's enterprise strategic capability teams across the globe and commercial divisions are working to be a conduit for providers to increase the marketability and scalability of their offerings and for product designers to gain a complete package that realizes the full scope of benefits that flexible electronics has to offer.

Printed Electronics

Printed electronics produce thinner, lighter, and more flexible circuit assemblies for the production of highly integrated products.

This low-cost additive manufacturing process enables any company to take advantage of this game-changing technology and functionality.