3D Printing Materials and Processes Guide

This 3D printing materials guide is designed to give you high-level information on the most commonly used 3D printing materials and processes. In this resource we cover materials and current trends around additive manufacturing materials. We also provide guidance on common 3D printing processes such as material extrusion, jetting, powder bed fusion and VAT photopolymerization.

3D Printing Materials

After crafting ways to leverage everything from human tissue to chocolate to lunar dust, you must wonder, "What 3D printing material can we not use?"

The answer: maybe none.

As the popularity and applications of 3D printing continue to grow, so does the range of materials used to suit the diverse needs of varying products and industries. Here are some of the most common and utilitarian materials for additive manufacturing:

Plastics/Polymers

Plastics and polymers are currently the most used materials, no surprise given that they were one of the first materials adopted and are relatively cheap and typically lightweight. Although manufacturers would like to expand their use of other materials, the increasing variety of applications that can be leveraged with plastics and polymers ensures that they are in no danger of disappearing from the additive manufacturing scene.

Some of the most popular thermoplastics include:

- Acrylonitrile Butadiene Styrene (ABS): The most popular material in production applications of 3D printing, ABS is strong, durable and inexpensive. It is an ideal material for casings, jigs, fixtures and other end-use parts.

- Polyamide (PA): Also known as nylon, PA is stronger than ABS, albeit more expensive. It has a robust combination of physical properties, including significant ductility, making it a popular choice for functional prototypes.

- Polycarbonate (PC): In addition to being light and dense with exceptional tensile strength, PC is highly impact resistant. When reinforced with fibers, it can be used to print parts with exceptional stiffness and strength.

Metals

According to Jabil's 2021 3D Printing Technology Trends survey, metal is the second 3D printing material that manufacturers would most like to use if certified versions were available at a reasonable cost. Seven in 10 respondents said they would like to use metal. Download the full Jabil survey report.

In many ways, metal 3D printing makes the job of manufacturers easier. While some materials, like polymers, essentially require the development of a new materials industry for 3D printing, additive manufacturers can use previously existing wire, metal powders or feedstock. While metal is difficult to use in conventional manufacturing methods, with 3D printing, manufacturers can more easily make parts from the same material that they would normally machine.

As a general rule, any metal that welds or casts well will work with additive manufacturing. Some popular metals used in 3D printing include:

- Steel: A notoriously strong, fatigue-resistant and, compared to most metals, highly affordable option, engineers and scientists are using steel in high-pressure, high temperature environments, where weight is of low concern.

- Titanium: Light, strong and biocompatible, titanium is especially popular for 3D printing in aerospace and medical applications, such as implants.

- Aluminum: Although not as strong as steel or titanium, aluminum is more resistant to corrosion, lightweight and versatile, making it ideal for auto racing components. It also provides the opportunity to create thin parts with fine details.

Ceramics

Ceramics have superior mechanical properties under compression and at higher temperatures than metals and plastics, and they possess electrical and thermal conductivities that can be leveraged for a wide range of applications. They are particularly gaining popularity in the aerospace and automotive industries. With their light weight and heat-resistance abilities, ceramics can withstand high levels of heat without breaking or warping. These qualities make it an ideal material for high-temperature applications.

Composites

Composites—two materials that have been melded into one with synergies neither raw material possesses on its own—provide excellent combinations of physical properties and processability. They are recommended materials for tooling and functional parts. Because of their weight optimization as well as significant strength and durability, composites are an advantageous choice when fashioning a very large or geometrically complex part for lightweight aircraft and cars.

Some currently popular composite material fillers for thermoplastics include carbon and glass fiber, but the variety of composites is constantly expanding and becoming more complex. Depending on the filler used in thermoplastic composites, the composite may be thermally conductive or insulative, electrically conductive or insulative, lightweight or heavy, stiff or soft. Composite materials can address many engineering challenges.

Custom Engineered Materials

Right now, the scope of products or 3D printing applications that companies can develop is limited by certified material options. At Jabil, we've noticed more companies requesting custom and advanced materials with specific strength, chemical resistance or machine integration properties. They are increasingly choosing custom engineered materials created specifically to optimize the efficiency and durability of their goods, whether that means formulating for specific properties such as reinforced, flame retardant, conductive, lubricated, Electrostatic Dissipative (ESD), etc.

This means that they need materials that can be created and certified quickly. Jabil took proactive steps to meet this growing demand by opening the Jabil Materials Innovation Center in Chaska, Minnesota. There, the Jabil Engineered Materials teams create and produce end-to-end 3D printing solutions, encompassing polymer formulations, compound development and ISO 9001 Quality Management Systems (QMS) certification. These materials are often used to build tooling, jigs and fixtures, prototypes and production parts.

3D Printing Materials, Processes; Trends: An Ultimate Guide

Luke Rodgers & Willa Toren-Senn

3D Printing Materials Market Trends

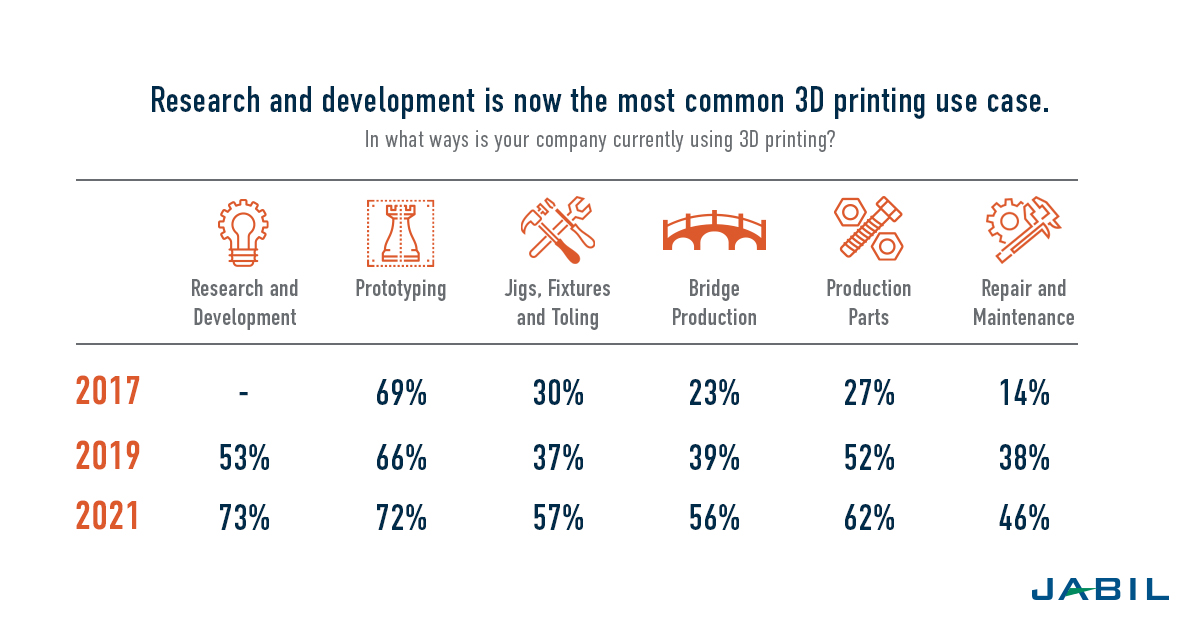

In just two years, 3D printing technologies have advanced dramatically, and additive manufacturing applications have skyrocketed. Whereas prototyping was the most common use-case in in previous years, research and development now tops use cases. Others, like production parts, bridge production, jigs, fixtures and tooling and repair have grown sharply in the last two years.

Even though the popularity and use of 3D printing have been increasing rapidly, there are still several challenges that brands must tackle. In the first additive manufacturing survey we conducted in 2017, the biggest 3D printing challenges were the cost of pre- and post-processing, the cost of system equipment, the lack of in-house expertise and cost of 3D printing materials.

Two years later, priorities have shifted from 3D printing technology to materials. This year, respondents listed the cost of materials, part quality, the cost of system equipment and the limited selection of materials as their largest challenges. Furthermore, 94% said that designers frequently choose traditional manufacturing methods due to the lack of additive manufacturing materials. But a lot will unfold with the bright future of 3D printing.

Over the years, as the technology and capabilities have evolved, some challenges have shifted. Today, the biggest challenges are the cost of pre- and post-processing, limited selection of materials and technology limitations.

Given the challenges manufacturers face with materials, it follows that 99% of participants stated that access to a greater variety of cost-effective, certified additive manufacturing will lead to greater use of 3D printing. As a result, six out of 10 participants believe they will increase the types of 3D printing applications and apply the technology to print more production parts.

While plastics and polymers remain the most popular and commonly available materials, when asked which materials participants would want to use when certified versions are available at a reasonable cost, the most common responses are metals and composites.

Additive manufacturing is currently going through the same progression that many industries have. Typically, industries have gone from using heavy metals to more polymeric materials, then converted over to light metals and finally end up using composites. This is the natural progression of material usefulness, and I believe additive manufacturing will follow the same progression.

The industry is currently in that transition of looking at lighter metals. The tools to economically and efficiently deliver solutions that can meet the requirements of the part designer are lacking, but once the industry finds its equilibrium, we'll start to see more conversion to whatever the right material is for each company's application.

One thing is certain in this industry: someday, additive manufacturing processes will be valuable tools in every engineer's toolbox. There will always be a place for injection molding, composite layup and castings; however, I do look forward to the day when every part that should be additively manufactured, is.

3D Printing Materials Compatible with Different Processes

| Plastic | Composite | Metal | Wax | Gypsum, Sand | Ceramic | |

|---|---|---|---|---|---|---|

| VAT Photopolymerization | X | X | X | |||

| Material Extrusion | X | X | ||||

| Material Jetting | X | X | X | X | ||

| Binder Jetting | X | X | X | |||

| Powder Bed Fusion | X | X | X |

3D Printing Processes

When 3D printing was first introduced in the 1980s, it sparked a revolution. Since then, 3D printers have settled into factories of various industries – everything from consumer goods to healthcare to aerospace – and have provided an entirely new set of capabilities, shortening production cycles, speeding prototyping and transforming the way engineers and designers approach their jobs—using design for additive manufacturing (DfAM).

To accommodate and expand this vast array of applications and leverage diverse material options, several additive manufacturing processes have been adopted and refined over the last 30-40 years. We examine the five 3D printing techniques and printer types:

VAT Photopolymerisation

In 1981, Dr. Hideo Kodama became the first person to develop a rapid prototyping technique at the Nagoya Municipal Industrial Research Institute in Japan, describing an approach to manufacturing that entailed constructing objects layer by layer. This idea set the foundation for the first stereolithography process, patented in 1984 by Charles Hull. Hull's stereolithography patent disclosed a stepwise photopolymerization process where the photopolymer selectively solidified via a directed beam of energy, according to a graphic pattern.

This innovation sparked the additive manufacturing revolution, and the concept is still commonly employed today, almost 40 years later. VAT Photopolymerisation processes are popular for rapid prototyping, casting and aerodynamic testing. Photopolymers, in general, suffer from low hygro/thermal mechanical properties and have limited UV resistance.

The subtypes of VAT photopolymerization are Stereolithography (SLA), Digital Light Processing (DLP) and Continuous Digital Light Processing (CDLP). There are many differences between these processes, but the major change from SLA to DLP was the use of a projection to selectively solidify the entire part layer at one time, versus a point-based laser, while CDLP took the stepwise methods for both Z height and light projection from DLP and replaced it with continuous processes.

Material Extrusion

In the material extrusion process, a continuous filament of thermoplastic or composite material is heated and disbursed through a nozzle, which proceeds to move horizontally and vertically over the build platform, adding to each layer. A common process for many inexpensive, domestic and hobby 3D printers, it is a highly popular additive manufacturing process in terms of availability for general consumer demand and quality. A relatively low-temperature process, it can operate without supervision, utilize a wide variety of materials and has low initial and running costs.

It is used in a variety of industries, from automotive to consumer goods, and is leveraged in many stages of the process, including development, prototyping and production. It can be used to print detailed end-use parts and is the most common process for jigs, fixtures and tooling. Material extrusion is referred to as Fused Deposition Modeling (FDM™) or Fused Filament Fabrication (FFF).

Material Jetting

Unlike VAT Photopolymerization, Material Jetting (MJ) doesn't require a vat of resin. Instead, a printhead similar to those used in standard inkjet printing dispenses droplets of photopolymer in a linear fashion on the desired areas of the build platform. As the droplets are deposited, an ultraviolet light attached to the Y bridge cures them. These systems can control their material deposition in a very small volumetric pixel, sometimes called a voxel. This ability to control very fine details of the deposition leads to a product with fine feature detail and a smooth surface finish.

Multiple inkjet printheads can simultaneously dispense different materials, enabling multi-material and full-color printing. Support structures are required, but dissolvable support structures are a straightforward and common solution. MJ-made 3D printed parts are best leveraged to print non-functional prototypes, and they are well-suited to fabricating realistic visual and haptic prototypes with surfaces smooth enough to resemble injection-molded parts.

Of all additive manufacturing processes, MJ offers the highest resolution and density, has larger size capabilities and offers the opportunity to work with multiple materials and support materials. However, the technology comes with a high price tag and there is a low selection of materials currently available. The two subtypes are Drop-On Demand (DOD) and Nano-Particle Jetting (NPJ). DOD uses a thermoplastic wax and is utilized almost exclusively for manufacturing investment casting patterns. NPJ printers are a combination of typical MJ printing, with embedded ceramics or metallic materials, producing a part like a binder jetting process but with finer feature detail.

Binder Jetting

The Binder Jetting (BJ) process starts with a re-coater that spreads a thin layer of powder over the build platform. Then, an inkjet nozzle applies a liquid bonding agent that effectively glues the particles of building material together, coalescing the various layers together to create a solidified part.

Binder jetting can be used with almost any powdered material. Additionally, because bonding occurs at room temperature, BJ avoids contortions caused by thermal variations (such as warping in FDM, SLS or DMSL/SLM or curling in SLA). However, the finished object tends to be in a "green" state, meaning that it has poor mechanical qualities and can be very fragile unless it is strengthened by further processing.

This manufacturing method is often used to create prototypes, which can be printed in full color, casting patterns and molds.

Powder Bed Fusion

All Powder Bed Fusion (PBF) methods of 3D printing start with a bed of powder spread over the build platform. Either a laser or electron beam is used to melt and fuse the powder together in the correct areas, then the build platform is lowered, and a new layer of powder is spread by the re-coater to create the next layer of the part. When the printing is finished, the leftover loose powder is removed, revealing the final object.

Most PBF methods do not require a support structure, which allows manufacturers to form more complex geometries. It is relatively inexpensive and can be used with a wide variety of materials. However, the process is hindered by the speed at which a powder material can be recoated onto the build platform. It also requires a large amount of power and the quality of the finish depends on the particle size.

PBF printing techniques include Multi Jet Fusion (MJF), Selective Laser Sintering (SLS), Direct Metal Laser Sintering/Selective Laser Melting (DMLS/SLM) and Electron Beam Melting (EBM). PBF is frequently leveraged to print series parts, prototypes for form/fit and functional testing and jigs, fixtures and tooling.

Closed vs. Open Platforms in 3D Printing

Closed platform printers run parameters and materials specified by the 3D printer OEM. These printers typically provide consistent results, with a good mix of aesthetics, physical properties and dimensional stability. These are typically great all-around printers but are less flexible for the advanced user who wishes to fine-tune their 3D printing process to create the best part performance for their application. Sole source procurement of materials and printers may also create an adoption problem, as some supply chain professionals won't allow sole source situations to occur in their product offerings.

Open platform printers allow users to experiment and build with any material or parameter of their choosing. The open platforms 3D printer typically requires a greater understanding of the technology and an advanced user to successfully implement these solutions. The open platform solutions can eliminate supply chain conflicts and provide the ability to fine-tune parts for greater aesthetics, physical properties or dimensional accuracy of the part. Open platforms allow the user to decide which combination of these three is the best solution for their application.

Download the 3D Printing Technology Trends Report

Jabil's third biennial report includes insights from over 300 individuals responsible for decisions around 3D printing at manufacturing companies on technology adoption, opportunities and challenges.