Capabilities

Advanced capabilities for real-world demands

Markets are shifting faster than ever, with rising customer expectations, global disruptions, and constant advances in technology reshaping how companies design, build, and deliver. Staying ahead requires the ability to adapt at a moment’s notice, whether it be by adopting new materials, using smarter automation, or expanding regional production.

Jabil addresses these needs through a comprehensive set of advanced capabilities in automation, electronics, metals, optics, plastics, and photonics. With a global network of over 100 sites, a strong digital infrastructure, and broad cross-industry experience, we enable flexible manufacturing that accelerates innovation, improves efficiency, and supports long-term growth for our customers across the world.

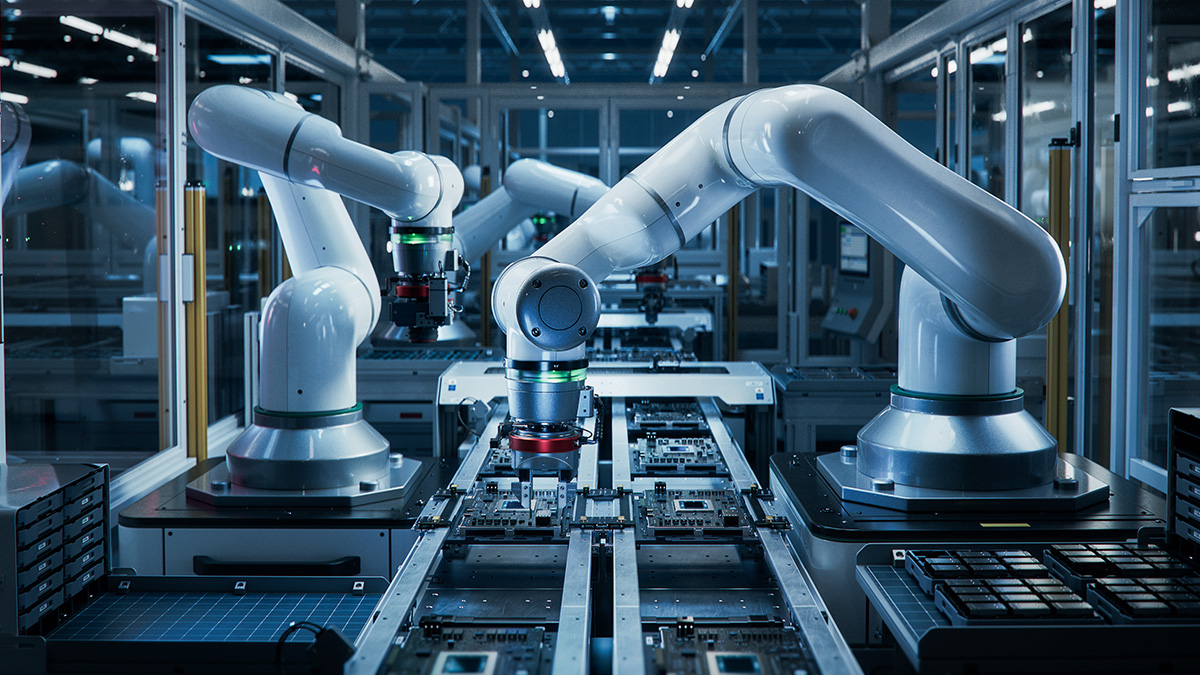

Automation

At Jabil, we help our customers define clear automation goals and align them with the right technical solutions. Our consultative approach, backed by deep engineering and hardware expertise, ensures every solution is built for long-term performance and seamless integration. Automation is embedded into our factory systems through standardized processes and rigorous design guidelines, enabling consistent execution and faster time to market across our global network.

Electronics

Jabil is one of the world’s leading electronics manufacturing services (EMS) providers, trusted by customers to deliver complex, high-performance electronic solutions from initial prototype to full-scale production. With a focus on precision, scalability, and speed, Jabil consistently meets exacting specifications while maintaining the highest standards of quality.

Large Form Factor Assembly

Jabil’s industry-leading supply chain and product lifecycle management capabilities enable efficient, reliable large form factor assembly solutions. With more than a dozen global facilities tailored for large form factor assembly, Jabil delivers the expertise and infrastructure needed to support your most ambitious builds.

Metals

Jabil’s advanced metals capabilities deliver the ideal balance of performance, quality, sustainability, and cost-efficiency to meet diverse product requirements. From precision components for automotive and aerospace applications to surgical instruments and consumer electronics, Jabil produces high-quality metal solutions that support innovation across industries.

Optics

Jabil’s optics capabilities are designed to meet today’s most complex challenges with end-to-end support across design, engineering, and production. Leveraging decades of experience and a global footprint, we deliver tailored manufacturing solutions that accelerate development, ensure scalability, and maintain quality from concept to mass production. Our optics engineers work within Jabil’s integrated ecosystem, gaining direct access to advanced tools, cross-functional expertise, and cutting-edge processes, enabling agile innovation and consistent execution. Trusted by leading brands across industries, we bring high-performance optical solutions to life for applications such as LiDAR, 3D sensing, imaging, and projection.

Plastics

Jabil’s vertically integrated plastics manufacturing capabilities accelerate product development, ensure consistent quality, and reduce total cost from prototype to production. As a one-stop partner, we offer expertise in injection molding, liquid silicone rubber molding, plastics assembly, inspection and test development, and additive manufacturing to deliver reliable solutions tailored to your needs.

Photonics

Jabil brings over a decade of experience in photonics, delivering customized solutions from high-speed transceivers to co-packaged optics. Our comprehensive capabilities span optical manufacturing services, advanced photonics packaging, design expertise, and flexible platform engagement models. Whether you need turnkey components or white-label options, Jabil’s integrated approach ensures precision, scalability, and speed-to-market for cutting-edge photonics applications.

How can Jabil solve your toughest product challenges?

Get in touch.