Semiconductor Wafer Handling Systems

Semiconductor manufacturers are often faced with the challenging task of finding new, more efficient ways to automate the handling of their wafers. Wafers come in a range of shapes and sizes, thus needing different handling requirements. So, figuring out an appropriate handling solution can sometimes pose a timely and costly challenge for manufacturers.

This is where Jabil Precision Automation can help. Whether it’s solving a complex wafer handling application or integrating automation into your current process tool; our proven experience and deep understanding of wafer handling automation and factory integration requirements allow us to develop wafer handling equipment that addresses all your project needs.

We design and build reliable, industry-trusted semiconductor wafer handling systems for some of the world’s leading semiconductor manufacturers around the globe. Whether it’s a turnkey Equipment Front End Module (EFEM) or a fully custom wafer handling solution -- our wafer handling know-how will ensure your next automation project is a success.

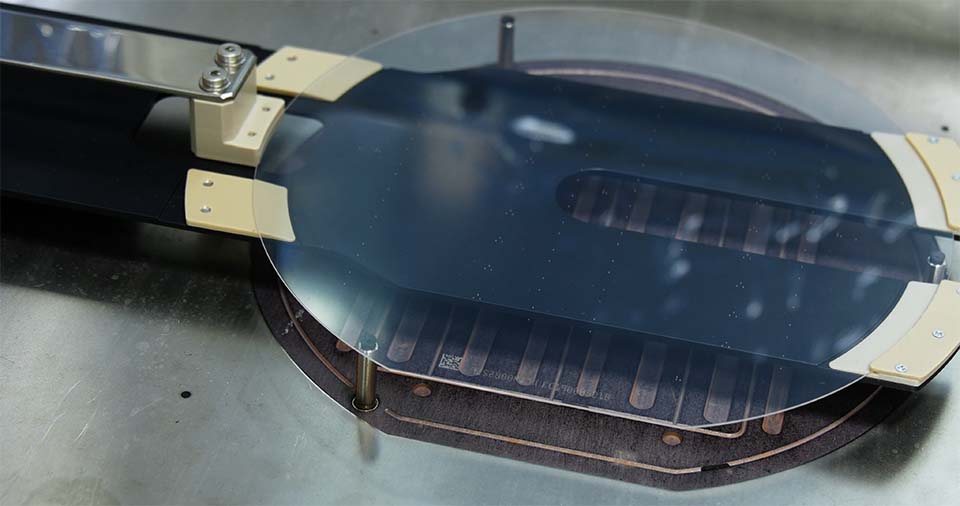

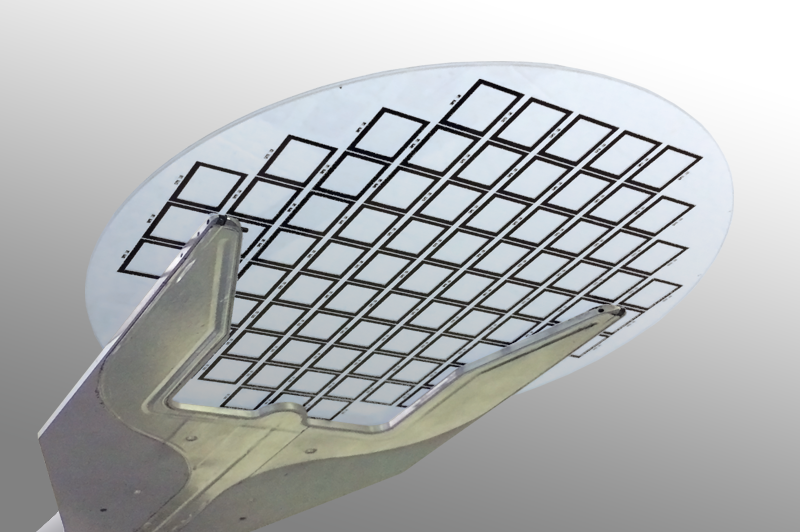

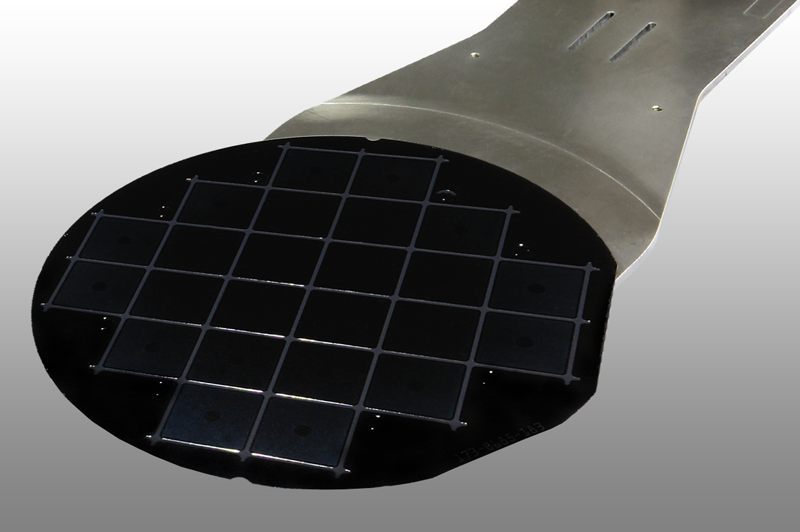

| Example: Coinstack Wafer Handling System |  |

What is a Wafer Handling System?

An automated wafer handler is a robotics system designed to automate and facilitate the handling of silicon wafers during the semiconductor manufacturing process. Wafer handlers are integrated with semiconductor process tools which perform various manufacturing tasks throughout the semiconductor production lifecycle. Automated wafer handling systems can be found throughout various Back End of Line (BEOL) or Front End of Line (FEOL) manufacturing processes as the robot facilitates the transfer of wafers between process tools.

Our mission is to provide you with a solution that facilitates the transfer of your wafers safely and efficiently during the manufacturing process.

Jabil Precision Automation Solutions offers a full range of automated wafer handling systems. Based on our standardized wafer handling automation platforms -- WaferMate 300 and WaferMate 200 -- our systems are highly-configurable and customized to meet your exact specifications.

| Example: Coinstack Wafer Handling System |  |

A typical wafer handling system consists of the following base components. Depending on the complexity or simplicity of the solutions, components can be customized to suit your wafer handling needs.

Wafer Carrier

A wafer carrier is used to store and transport wafers during the manufacturing process. We support the integration of a variety of wafer carriers and mini environments.

- FOUPs (Front Opening Universal Pods)

- Typically used with 300mm wafers applications

- FOSB Box (Front Opening Shipping Box)

- Stores wafers during transportation

- SMIF Pods (Standard Mechanical Interface)

- Typically used with 200mm wafer applications

- Open Cassettes

- Used with 200mm or smaller wafer applications

- Coinstack “Horizontal Wafer Stackers”

- Typically used transport fragile wafers (e.g. thin and warped wafers)

Wafer Pre-Aligner

The wafer aligner is an essential system tool that’s used to properly orientate the wafer before it’s handed off for processing. Proper positioning plays a crucial role in determining the level of accuracy and efficiency during manufacturing. A wide variety of wafer flats and notches can be accommodated.

Available Wafer Aligners:

- Vacuum (backside contact)

- Edge Grip (non-contact)

Wafer Handling Robot

The heart to any wafer handling system is the wafer handling robot. Paired up with a suitable end effector, the robot facilitates the handling of wafers between process steps.

Available Atmospheric Robot Options:

- Single Arm Robot

- Standard wafer handling robot used in a wide range of wafer handling applications

- Dual Arm Robot

- Reduce wafer swap times and overall cycle times

|

Example: Coinstack Wafer Handling System |

We understand the level of complexity that goes into wafer handling projects, that’s why we offer a range of available systems options to help develop a solution that supports your manufacturing goals.

Available System Options:

- Clean Air Fan Filter Unit (FFU) for up to ISO2 cleanliness

- Integrated Ionizers for ESD sensitive wafers

- Optical Character Recognition (OCR) Reader for alphanumeric scribes, barcodes, and Data Matrix Codes (DMC)

- Wafer Flipping Modules

- SECS/GEM Communication with facility host network

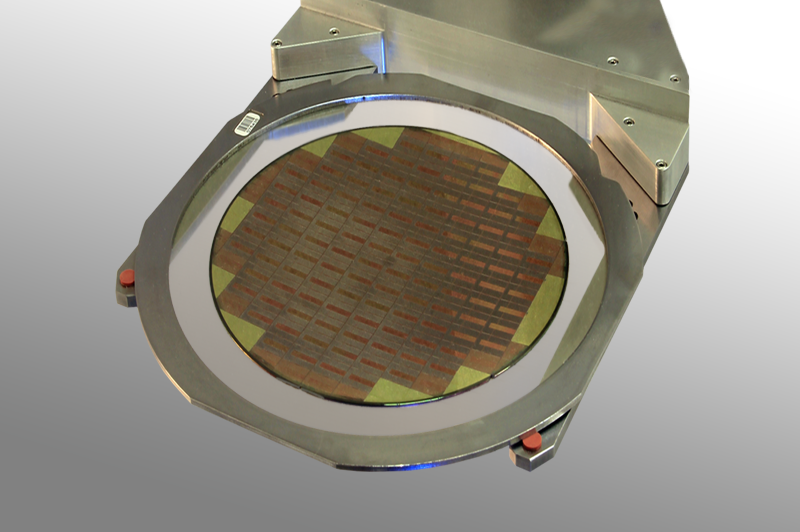

Supported Wafer Types:

We support the handling of a variety of wafer types and sizes that range from 100mm to 450mm.

- Thin Wafers (down to 50µm thickness)

- Thick Wafers

- Warped Wafers

- Bonded Wafers

- Trenched Wafers

- Glass Wafers

- Reticles & Photomasks

- Other substrates upon request

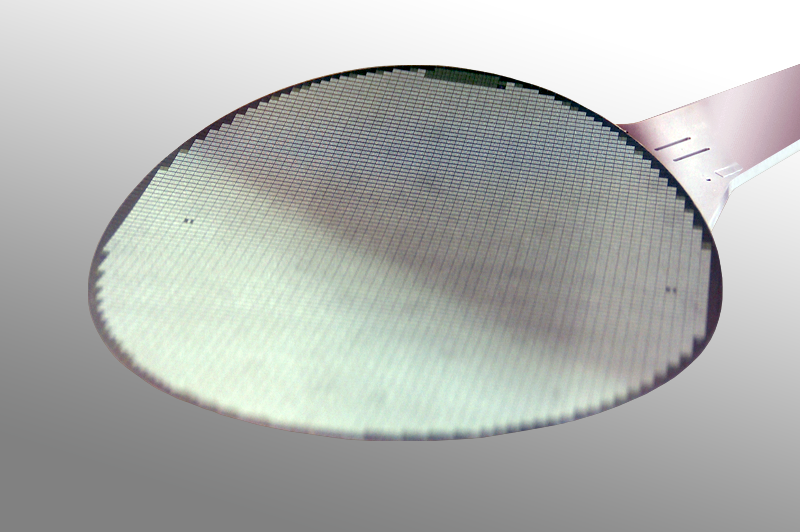

Warped Wafers

Warped Wafers

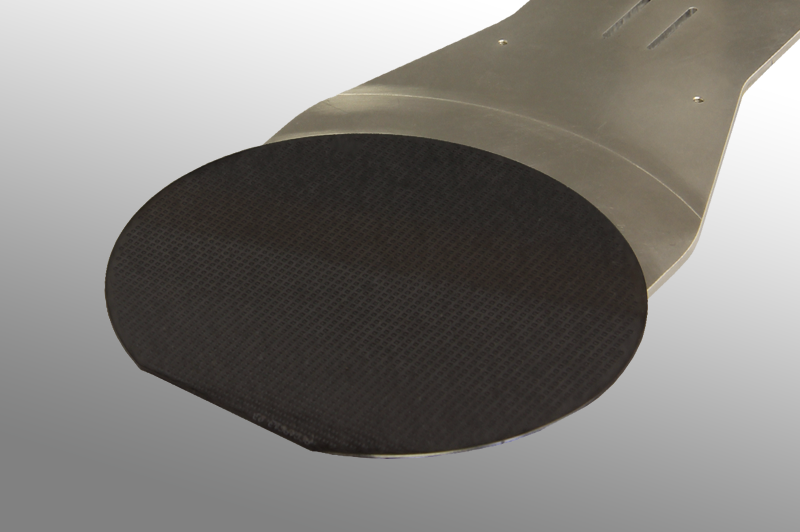

Film Frames

Film Frames

Thin Wafers

Thin Wafers

Glass Wafers

Glass Wafers

Glass Reticles

Glass Reticles

Grooved Wafers

Grooved Wafers

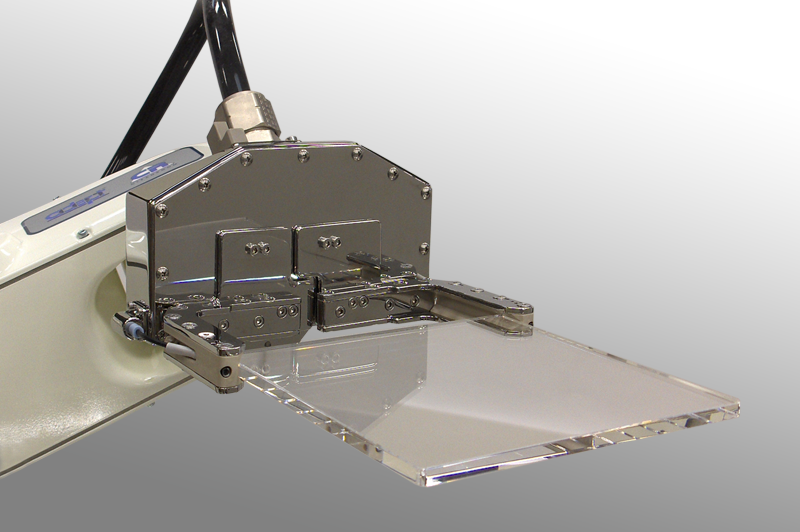

Available End Effector Technolgies

Wafer handling robots are paired with various end effectors that facilitates the handling of your wafers. We offer an extensive portfolio of patented end effector technologies that allow us to build systems that address your wafer handling needs.

- Non-Contact Bernoulli

- Perfect for applications dealing with wafers prone to contamination due to traditional handling methods.

- Vacuum Handling

- Standard gripping solution applicable to a wide variety of wafers and applications.

- Edge Grip Wafer

- Great for handling applications with contact exclusion zones

- Dual Wrist End Effectors

- Increases throughput, better cycle times, faster wafer swap times

| Example: Edge Grip Wafer End Effector with Glass Wafer |

|

Photomask Reticle Cleaning System

Non-Contact Wafer Handling

Benefits of Automated Wafer handling

Whether you’re transitioning from manual wafer handling or looking to integrate automation with your process tool – we have the experience to provide a solution that meets your needs.

- Increase Throughput and Yield

- Eliminate Damage to Expensive and Fragile Wafers

- Improved Accuracy and Repeatability

- Improved Quality Control and Traceability

Custom Semiconductor Wafer Handling Projects

In addition to standard silicon wafer handling applications, we also manufacture custom automated solutions, tailored to your specific need.

Examples:

- Reticle Cleaners

- Reticle Sorters

- Coinstack Packers

- Pallet + Wafer Applications

| Example: Custom Glass Reticle Sorter System |  |

Ready to Automate?

Get in touch with one of our automation experts

Capabilities

-

Motion Control

Jabil Precision Automation designs motion control systems used for custom robotic solutions tailored to our customers applications.

LEARN MORE -

Precision Alignment

Our precision alignment solutions are paired with vision system hardware to meet precision alignment requirements for wafer etching, optics assembly & more.

LEARN MORE -

Inspection and Testing

We know what it takes to tackle sub-micron precision inspection and testing. Our knowledge allows us to deliver cutting-edge precision capabilities.

LEARN MORE -

Factory Automation Software

Jabil Precision Automation's factory automation software delivers robust capabilities that delivers intelligent manufacturing straight to the factory floor.

LEARN MORE

Industries Served

-

Semiconductor

Automating the semiconductor manufacturing process with high-performance wafer handling systems. Our systems offer support for a wide range of processes, wafer sizes, and types.

LEARN MORE -

AR & VR Devices

When it comes to material handling solutions for Augmented and Virtual Reality devices, we tackle the most complicated, high-precision material handling challenges head on by delivering automated solutions…

LEARN MORE -

Solar & Energy Devices

Solar devices & energy manufacturing involves thin and fragile components that requiring a high-degree of control and precision when handling because of very tight tolerances on it's connecting features.…

LEARN MORE -

Automotive

Jabil Precision Automation delivers automotive automation assembly solutions for electronic components such as infotainment systems, engine control modules, sensors, and dashboard assemblies for the automotive…

LEARN MORE -

Medical Devices

Our proven track record for high precision electronics assembly automation in healthcare helps us deliver automation solutions for medical devices.

LEARN MORE -

Wearable Technology

Jabil Precision Automation tackles intricate assembly processes in connected manufacturing by delivering multiple automated assembly processes, such as adhesive dispensing systems, curing, vision-guided…

LEARN MORE