Jabil Precision Automation Solutions has been building equipment for over 25 years to assemble automotive electronic components for infotainment systems, engine controls, airbag controls, electric seat controls, and dashboard assemblies for automobiles, construction equipment, lift trucks, golf carts, and more.

Automotive automation assemblies are typically medium to high volume, low mix type products that have very demanding quality and yield requirements, strict delivery schedules, and very high-reliability standards

Additionally, industry regulations and customers require traceability down to the component level. Therefore, we offer solutions that can collect crucial bar code information from circuit boards, component packaging, or precisely place barcode labels on the assembled device.

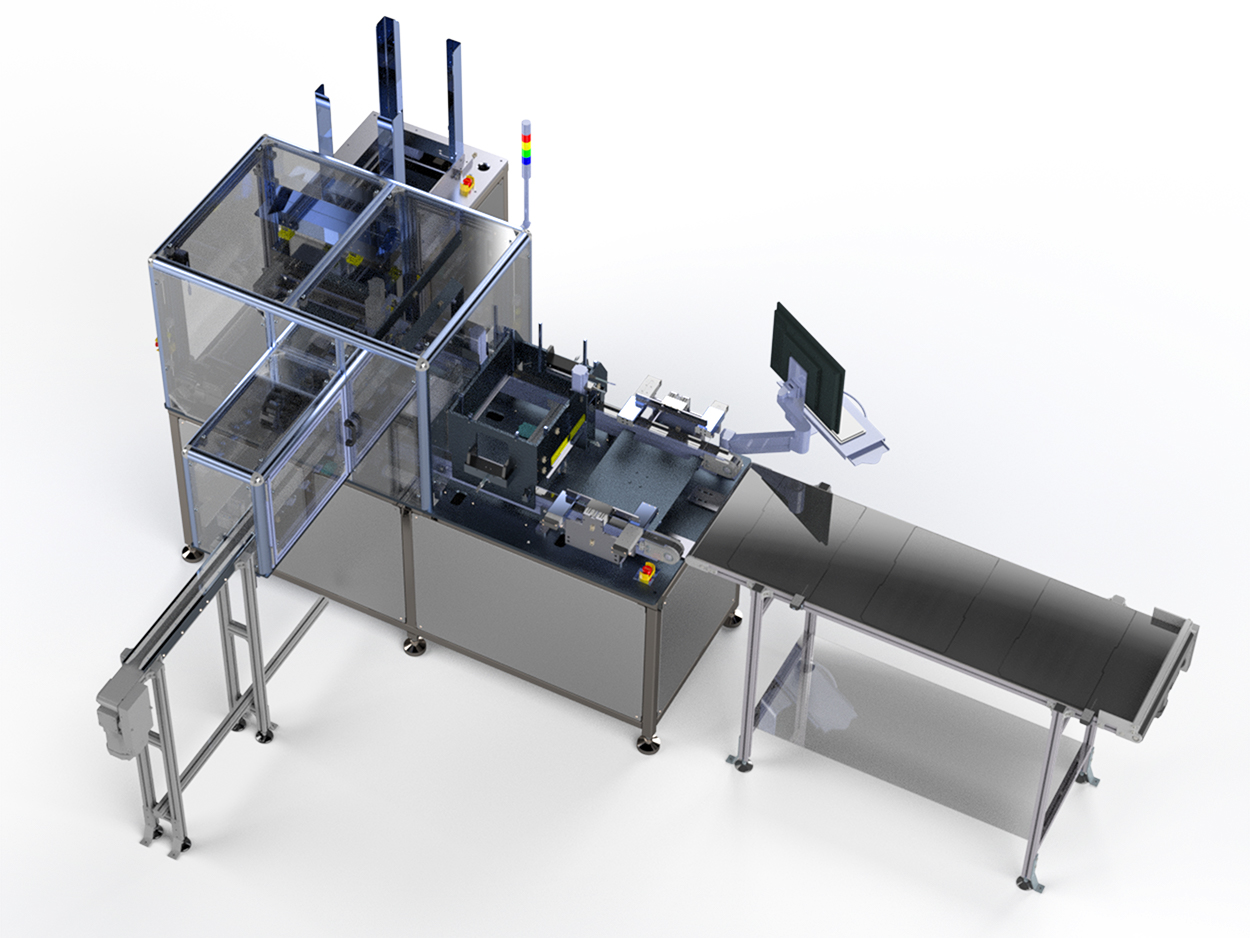

Typical automotive automation applications require a work cell that can handle a variety of odd-form components – so we’ve developed a solution designed to handle all your automotive automation needs. The IQPS work cell was built specifically to handle large capacitors, large connectors, and other odd-form components.

If you're in the need of more back-end assembly process automation, the SIM work cell delivers automotive automation capabilities such as – like point to point soldering, masking and sealing, enclosure assembly, screw fastening, and more.

Capabilities

-

Point to Point Soldering

-

Masking & Sealing

-

Enclosure Assembly

-

Screw Fastening

-

Dispensing

-

Welding

-

PCB Assembly

-

Inspection & Testing

Applications

-

Engine & Powertrain Control Modules

-

Passive and Active Safety Sensors

-

Comfort and Security Features

-

Infotainment Modules

-

Heads Up Displays (HUDs)

-

LiDar Modules

Custom Automated Manufacturing Systems

Automated Material Handling System

This custom solution was built to automate the loading, stacking, and inspection of finished parts trays for a large automotive component supplier.

Contact Us

Get in touch with one of our automation experts and see how we can help with your next automation project.

Related Content

-

Resources

Watch the latest Jabil Precision Automation videos right here. Here you'll find the latest examples of precision automation, wafer handling applications and more.

LEARN MORE -

Precision Alignment

Our precision alignment solutions are paired with vision system hardware to meet precision alignment requirements for wafer etching, optics assembly & more.

LEARN MORE

Ready to Automate?

Get in touch with one of our automation experts