Description

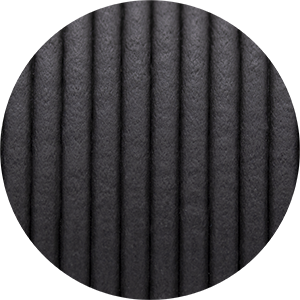

PA 4035 CF is an ESD-safe (electrostatic dissipative), carbon-fiber-reinforced PA12 copolymer providing greater stiffness, strength and toughness over similar materials on the market.

Great for printing items that require extra strength and stiffness.

Material

- High strength, stiffness and toughness

- High-impact strength

- Superior printed part surface finish quality

- Surface resistivity of ≤E9 for ESD sensitive applications

- Mechanical properties can be tailored by adjusting fill orientation

Color

Black

Printing

- Easy-handling filament features reduced breakage during loading and printing

- Low print temperature enables usage on more machines

- Prints on any open-source desktop 3D printer using filaments including new high-speed printers such as Bambu Labs X1C and X1E

For the latest print profiles, search for Jabil Engineered Materials in the Cura Marketplace

Applications

- Ducting for automotive and aerospace

- Casting patterns

- Composite tooling

- Prosthetics

- Aluminum replacement

Industries

- Automotive

- Aerospace

- General manufacturing

- Medical

Comparison

- Increased stiffness and strength in load-bearing orientations while showing less warping than standard nylon

- Higher dimensional stability compared to standard nylon from carbon fiber

Shop now

Get In Touch

Custom additive materials, filaments, digital parts and more. Get started with a trusted additive partner.