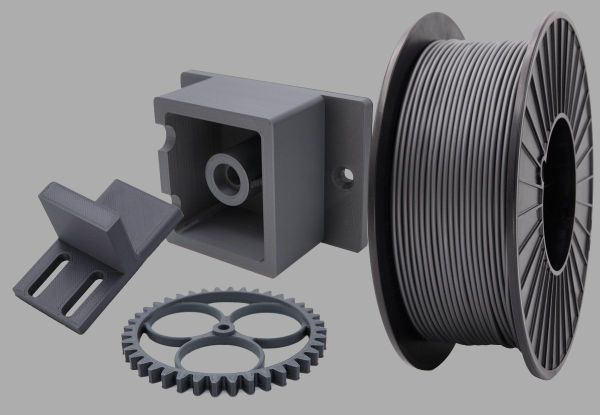

Jabil’s PA 0600 filament is a polyamide/polyketone alloy with high stiffness, good wear resistance, low friction and self-lubricating characteristics. The high stiffness and self-lubricating qualities make post-print machining, such as fly cuts, thread taps and heat stakes, simple and effective.

Compared to other tribologically similar polymers such as POM and PVDF, which are commonly used for similar applications, Jabil PA 0600 releases no odors or toxic fumes during processing, exhibits low warp and has similar dynamic and static coefficient of friction.

Material

- Excellent machinability

- High strength and stiffness

- Good wear and abrasion resistance

- Low coefficient of friction

- Excellent chemical resistance

- Low warp

- Good dimensional stability

- Non-marring

Printing

- Prints on open platforms including Ultimaker S5, UM 3, Raise3D, Method X and Taz® Pro Platforms

- Processes in the mid-range of most desktop printers (print temp 230 - 250 °C, build plate temp 50 - 60 °C)

- Due to functional additives, larger nozzles (≥0.6 mm) will provide best results, while a 0.4mm nozzle will still achieve outstanding results

Applications

Any application where high dimensional stability and lubricity is required

- Gears, bearings and rollers

- Parts requiring knurling

- Jigs, fixtures and tooling

- Work-holding devices, posts, nests etc.

Industries

- General manufacturing

- Automotive

- Aerospace

Shop now

Get In Touch

Custom additive materials, filaments, digital parts and more. Get started with a trusted additive partner.